What is a Garment Size Label? Where to Customize It?

Introduction to Garment Size Labels

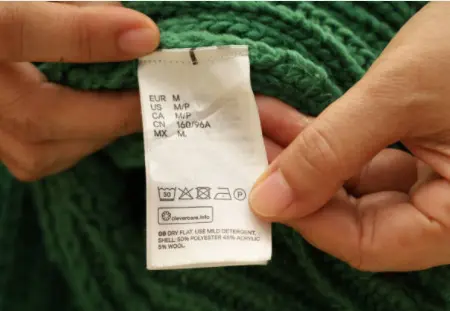

As an indispensable component of apparel products, garment size labels are not only the direct basis for consumers to choose the right size, but also an important window for clothing enterprises to implement standardized management and display their brand image.

Functions of Garment Size Labels

Garment size labels are identification tools specially used in the clothing production and sales process. Their main function is to clearly display clothing size information, helping consumers and merchants quickly identify product sizes. Such labels are usually directly pasted on clothing packages, some are affixed to garments, and there are also woven labels sewn inside the clothes.

Compared with traditional sewn labels, self-adhesive size labels have obvious advantages: easy to paste and replace, can contain multiple information such as price and promotions, and improve inventory management efficiency. Size markings usually adopt two forms: internationally accepted letter notations (e.g., XS, S, M, L, XL) and the combination of height and bust specified in China's national standards (e.g., 160/80A).

At present, there are phenomena such as size shrinkage of women's clothing in the market, which makes standardized size labels more important, as they can effectively reduce consumer disputes caused by inconsistent sizes.

Material Selection for Garment Size Labels

The material selection of garment size labels directly affects their use effect and consumer experience. Currently, the mainstream materials on the market mainly include the following categories:

① PE Self-adhesive: Made of garment latex white PE material, it has the characteristics of strong adhesion, removability, good elasticity and waterproofness, which is particularly in line with the characteristic requirements of clothing fabrics. This material leaves no adhesive residue when torn off and will not damage clothing fibers, making it an ideal choice for high-end apparel.

② Coated Paper Self-adhesive: Low in cost and good in printing effect, it is suitable for clothing labels used in dry environments, but does not have waterproof properties.

③ PVC Material: Transparent or white PVC material has excellent waterproof and oil-resistant performance, and is wear-resistant and durable, suitable for sportswear and outdoor clothing.

④ Woven Label Material: Woven with 100% pure cotton and directly sewn on clothing, it is soft to the touch and will not irritate the skin, making it especially suitable for high-end brands and infant clothing.

⑤ Synthetic Paper: It has a balanced performance in durability and economy, and is applicable to various clothing packaging environments.

Considering applicability, cost and performance comprehensively, PE self-adhesive has the best cost performance among various materials. It not only meets the core requirement of being removable without leaving adhesive residue, but also maintains a relatively reasonable cost.

Customization Processes for Garment Size Labels

Modern customization of garment size labels supports a variety of advanced printing processes and technical treatments to meet the personalized needs of different brands:

① Letterpress Printing, as a mainstream technology, can achieve high-definition color printing with high precision and bright colors.

② Lamination Process (glossy film or matte film) can improve the waterproof, sunproof and wear-resistant performance of labels, extending their service life.

③ Hot Stamping Process adds a sense of high-grade and recognition to brand labels, suitable for luxury goods and brand customization.

④ Spot Color Printing (Pantone spot colors) ensures the accurate reproduction of brand colors and maintains the consistency of brand image.

⑤ Label shapes can be customized into round, rectangular, square or irregular shapes to meet the labeling needs of different clothing brands.

Applications of Garment Size Labels

The significant advantages of high-quality garment size labels are mainly reflected in the following aspects:

① Strong Adhesion and Removability is the core advantage, ensuring that the label is firmly pasted, and at the same time, no adhesive residue is left when removed, avoiding damage to clothing fabrics.

② Waterproof and Oil-resistant Properties enable the label to adapt to various storage and transportation environments, keeping the information clear and readable.

③ Environmentally Friendly Materials conform to the concept of modern sustainable development. Some products use ROHS-certified environmentally friendly materials, which are safe and non-toxic.

④ Wide Applicability: It can be applied to various fabrics such as cotton, linen, silk, wool and synthetic fibers.

Garment size labels are widely used in various clothing scenarios, including but not limited to: size marking of adult and children's clothing, inventory management of e-commerce clothing, price labels for promotional activities, and brand information display of clothing brands.

Size and Position Standards for Garment Size Labels

Garment size labels used in different positions have their conventional size standards:

① Round Labels: The diameter is usually between 10mm and 30mm, with 12mm-15mm being the most common, suitable for size marking of clothing, shoes and hats.

② Rectangular Labels: Available in various sizes, such as 165×32mm, 132×35mm, etc., they are more suitable for containing more information, such as size, price and promotion content.

According to the application scenarios and label types, the thickness of size labels is generally between 0.12mm-0.16mm to ensure flexibility and pasting effect.

The position of garment size labels on clothing also has certain specifications: the main label is usually located under the back collar inside the top or at the back center seam inside the bottom garment; the size label may be combined with the main label or sewn near the main label; the sleeve label is located beside the cuff.

Recommended Supplier of Garment Size Labels: China LIJIE Factory

Among numerous garment size label manufacturers, China LIJIE Factory stands out with its outstanding strength and has become a leader in the industry. The factory has a 4,000-square-meter modern production base, equipped with 30 advanced processing equipment, achieving a large-scale production capacity of 1.2 million garment size labels per day.

LIJIE Factory has served more than 2,000 customers and has performed excellently in terms of product quality, delivery time and after-sales service. The factory holds a number of international compliance certifications such as SGS certification, ROHS certification and CE certification, ensuring that product quality meets international standards.

To meet the needs of different customers, LIJIE Factory provides flexible customization services. The minimum order quantity for woven size labels is 3,000 pieces, with a unit price of only 0.07, truly achieving a perfect combination of high quality and low price.

The factory supports customization of various materials and processes, and can provide personalized solutions according to customer needs, with professional guidance throughout the process from design to production, ensuring that each customer can obtain the most suitable garment size label products.