Where to Wholesale Branded Poly Bags? How much?

Where to Wholesale Branded Poly Bags?

In today’s highly competitive market environment, branded poly bags are no longer just simple packaging tools—they have evolved into important carriers for corporate image display and brand promotion. Whether for retail stores, supermarkets, or various enterprises, customizing exclusive plastic bags can effectively enhance brand recognition, turning every product delivery into an opportunity for brand communication.

What Are Branded Poly Bags?

Branded poly bags refer to a variety of plastic bags customized according to enterprises’ specific needs, printed with corporate logos and promotional information. They not only serve the basic functions of packaging and protection but also act as mobile billboards for corporate images. When consumers carry plastic bags printed with brand logos through streets and alleys, they inadvertently achieve secondary brand promotion—a cost-effective marketing method with wide reach.

Common Materials of Plastic Bags

Selecting the right material is the crucial first step in customizing plastic bags. Different materials have distinct characteristics and applicable scenarios:

① PE (Polyethylene): The most common material for plastic bags, featuring excellent flexibility, tear resistance, and moisture resistance. PE plastic bags are typically used for packaging food, cosmetics, pharmaceuticals, etc., providing good sealing performance. PE is further divided into HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene). Among them, HDPE bags are rigid and sturdy, commonly used as supermarket shopping bags.

② PP (Polypropylene): Boasts high transparency and hardness, making it suitable for scenarios requiring high clarity, such as bread bags and food packaging bags. PP material has good heat resistance and can be used for packaging products that need high-temperature sterilization.

③ OPP (Oriented Polypropylene): The plastic bag material with the highest transparency, delivering exceptional printing results. However, it has poor toughness and is prone to tearing, so it is often used for packaging lightweight goods like stationery and accessories.

④ CPP (Cast Polypropylene): Offers excellent transparency and heat resistance, widely applied in packaging food, daily necessities, and other products.

⑤ Composite Materials: Such as VMPET (Vacuum Metallized Polyester Film) and AL (Aluminum Foil), these materials have outstanding barrier properties, effectively blocking oxygen, moisture, and light. They are commonly used for packaging products requiring long-term freshness preservation, including coffee, dried fruits, and meats.

Customization Process of Branded Poly Bags

Customizing branded poly bags is a systematic process. Following these steps ensures the final product meets expectations:

1. Provide Customization Requirement Document: Submit detailed customization specifications to the manufacturer, including the exact dimensions of the plastic bags (height, width, side gusset), material requirements, color standards, printing content (LOGO, brand name, contact information, etc.), and estimated order quantity.

2. Manufacturer Issues Quotation: The plastic bag manufacturer designs according to the customer’s requirements and provides a quotation. Pricing is usually determined based on material costs, printing complexity, and order volume.

3. Customer Confirmation and Payment: After the customer is satisfied with the sample and quotation, confirm the order and pay a deposit or full payment. Formal manufacturers will provide a standard contract and quality assurance agreement at this stage.

4. Production and Processing: The manufacturer arranges production upon receiving payment. Modern plastic bag production includes processes such as film blowing, cutting and sealing, and printing.

5. Quality Inspection and Delivery: After production is completed, the manufacturer conducts quality inspection. Once confirmed to be qualified, the products are shipped via international logistics services such as DHL, UPS, or FedEx.

Customization Techniques and Size Selection for Plastic Bags

Common Process Options

① Printing Techniques: Supports multiple methods including screen printing, gravure printing, and flexographic printing. The choice can be made based on design complexity and budget.

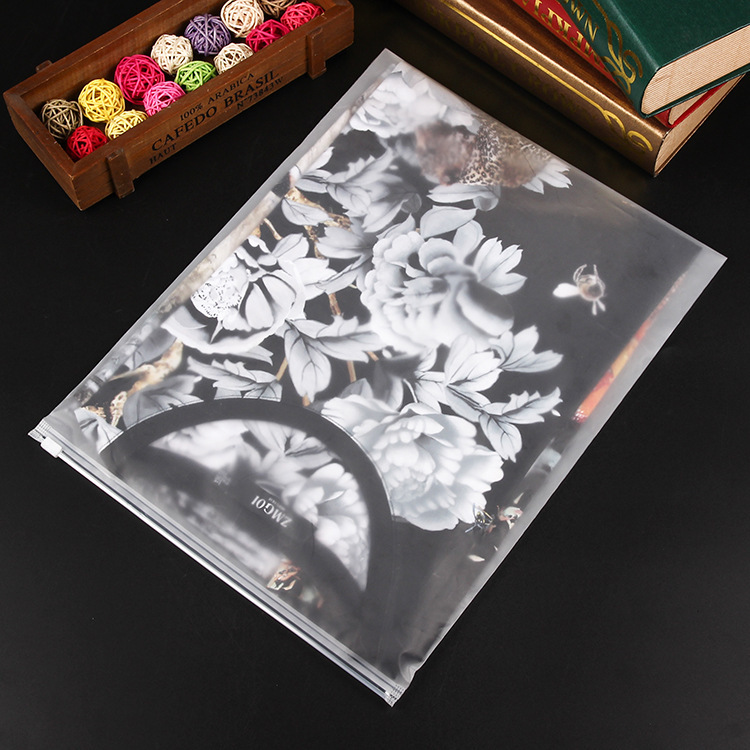

② Bag Type Design: Various bag types are available for customization, such as flat bags, vest bags, ziplock bags, and stand-up pouches.

③ Additional Functions: Accessories like zippers, handles, and air holes can be added as needed to enhance the functionality and convenience of the packaging bags.

Reference for Regular Sizes

The size of plastic bags can be flexibly customized according to the contents. Common specifications include:

① Small-sized Bags: Approximately 20×30cm, suitable for small commodities and accessories.

② Medium-sized Bags: Approximately 30×40cm, ideal for clothing and daily necessities.

③ Large-sized Bags: Above 40×50cm, designed for bulky goods and bulk products.

Manufacturer of Branded Poly Bags: LIJIE China

Among numerous plastic bag manufacturers, LIJIE Factory stands out with its professional production capacity and stringent quality standards, making it an ideal choice for branded poly bag customization.

1. Outstanding Corporate Strength

LIJIE Factory owns a 4,000 m² modern production base, with a daily output of up to 300,000 branded poly bags. It has served more than 2,000 customers, accumulating rich industry experience. Equipped with 30 sets of advanced processing equipment, the factory can meet various complex customization needs.

2. Complete Certifications & Quality Assurance

LIJIE Factory has obtained multiple international standard certifications including SGS, ROHS, and CE, ensuring that product quality complies with domestic and foreign environmental protection and safety requirements. In today’s era of growing environmental awareness, LIJIE Factory adopts eco-friendly materials and production processes, actively responding to national environmental protection policies.

3. High Cost-Effectiveness & Reasonable MOQ

LIJIE Factory offers highly competitive prices. The minimum order quantity (MOQ) for branded poly bag customization is 3,000 units, with unit prices ranging from USD 0.17 to 0.45. The specific price is determined by the material and process complexity. This pricing strategy not only meets the customization needs of small and medium-sized enterprises but also ensures cost-effectiveness.