How Much Does It Cost to Customize Non Woven Tote Bags?

What Are Non Woven Tote Bags?

Non Woven tote bags are made from spunbond polypropylene (PP) through mechanical, thermal, or chemical bonding processes (without traditional weaving), and customized with printed logos, patterns, or text. Lightweight yet durable, breathable, eco-friendly, reusable, and easily degradable, they align with green development concepts. Featuring excellent printability, they can meet diverse personalized customization needs.

They boast a wide range of applications:

① Serving as brand promotion carriers for exhibitions and promotions to enhance brand exposure.

② Being ideal for daily scenarios such as supermarket shopping, gift packaging, and clothing storage.

③ Coated Non Woven tote bags are also suitable for food delivery and fresh produce distribution, combining practicality with marketing value.

Custom Materials for Non Woven Tote Bags

Material selection affects the cost, durability, and applicable scenarios of the bags. There are three mainstream custom material options:

1. PP Non Woven Bags

① The basic and most popular option, with a grammage of 60–100g.

② Lightweight, featuring vivid printing effects and low cost, it can bear a load of 3–5kg.

③ Suitable for regular scenarios like promotions and daily shopping.

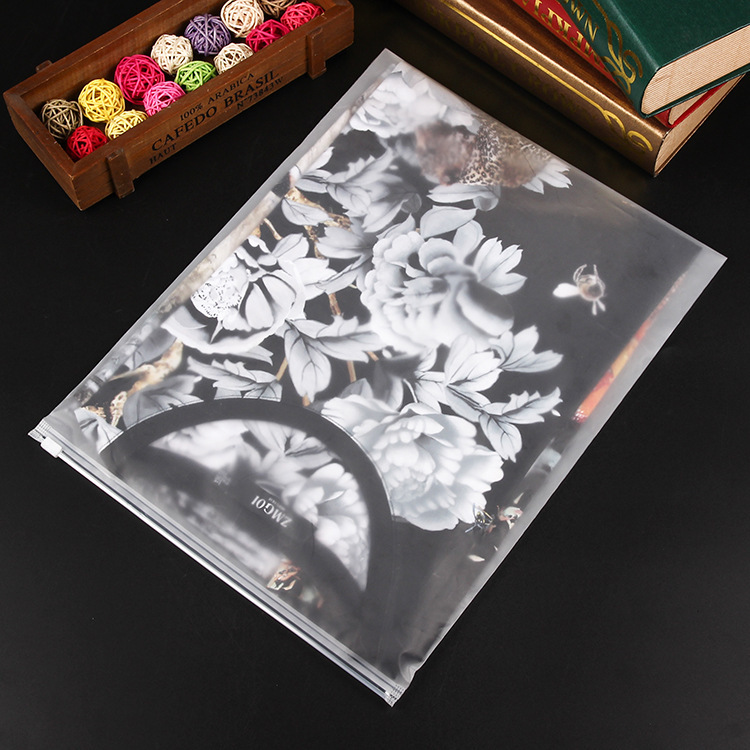

2. Coated Non Woven Bags

① Made of PP Non Woven fabric laminated with PE film, it is waterproof, oil-proof, and moisture-proof.

② Heat-sealed seams prevent leakage. With a grammage of 80–125g, it can bear a load of 8–10kg.

③ Ideal for food delivery and fresh produce distribution.

3. RPET Recycled Non Woven Bags

① Made from recycled PET bottles, it offers outstanding environmental performance and can provide GRS certification.

② Suitable for high-end brands and cross-border enterprises, with a relatively higher cost.

Which Material of Non Woven Tote Bag Is the Most Commonly Used and Cost-Effective?

PP Non Woven bags are the most commonly used and cheapest type, accounting for over 60% of custom orders, and are highly favored by small and medium-sized enterprises as well as promotion purchasers.

They deliver exceptional cost-effectiveness: the 60–80g variant has the lowest unit price when purchased in bulk, with high-quality printing and a short production cycle, making it suitable for scenarios without special protection requirements. For waterproof and oil-proof needs, a lamination process can be added, which slightly increases the cost but significantly improves practicality.

Custom Processes Available for Non Woven Tote Bags

Printing processes determine the visual effect and durability of the bags. There are three mainstream processes to meet different needs and budgets:

1. Screen Printing

① The most cost-effective option, suitable for single-color or few-color logos and text.

② Featuring clear and wear-resistant prints at a low cost, it is the first choice for large-batch promotional and advertising bags.

2. Heat Transfer Printing

① Suitable for full-color and complex patterns, producing delicate and vibrant colors.

② Ideal for small-batch high-end gift bags, with a higher cost than screen printing.

3. Lamination Printing

① Used in conjunction with coated Non Woven materials, it supports full-color printing and is waterproof.

② Suitable for scenarios such as food delivery and fresh produce packaging.

Regular Sizes of Non Woven Tote Bags

Sizes can be customized according to needs. The mainstream regular sizes and their applicable scenarios are as follows:

(1) Shopping Bags: 33cm × 38cm × 10cm, 35cm × 40cm × 12cm (gusset width)

① Universally suitable for supermarket shopping and clothing storage.

(2) Gift Bags: 25cm × 30cm × 8cm, 20cm × 25cm × 6cm (gusset width)

① Compact size, perfect for packaging gifts, cosmetics, and stationery.

(3) Storage/Portable Bags: 25cm × 30cm × 15cm, 30cm × 35cm × 10cm (gusset width)

① Suitable for daily storage and on-the-go use.

(4) Extra-Large Bags: 40cm × 45cm × 15cm (gusset width) and above

① Ideal for storing large items, industrial use, and holding materials for large-scale events.

Customization Process for Non Woven Tote Bags

The standardized customization process is simple and efficient, tailored for cross-border procurement:

1. Submit Requirements

Send a detailed document specifying the size, material, color, logo, quantity, and special processes (e.g., handles, reinforcement).

2. Quotation Issuance

Receive a formal quotation within 1–2 working days, clarifying the unit price, production cycle, shipping fees, and other details.

3. Confirmation and Payment

After verifying the quotation, the customer pays the deposit or full payment as agreed.

4. Production Arrangement

Production starts upon receipt of payment, with strict quality and process control throughout the entire production cycle.

5. Delivery

After passing quality inspection, the goods are shipped via DHL, UPS, or FedEx, and the tracking number is provided to the customer.

Custom Non Woven Tote Bags from LIJIE Factory, China

For wholesale customization, LIJIE Factory in China is the top choice. As a leading manufacturer in the industry, it serves over 2,000 customers worldwide with strong production capacity, strict quality control, and high cost-effectiveness.

(1) Strong Production Capacity

① Equipped with a 4,000㎡ workshop and 30 sets of advanced equipment, it achieves a daily output of 30,000 bags.

② Capable of efficiently fulfilling large-batch and urgent orders while ensuring on-time delivery.

(2) Compliance Assurance

① Certified by SGS, ROHS, and CE, the factory uses eco-friendly materials that meet global trade standards, ensuring worry-free cross-border procurement.

(3) High Cost-Effectiveness

① As a direct factory supplier without middlemen, it offers a minimum order quantity of 3,000 bags, with a unit price ranging from ![]() 0.76, balancing high quality and competitive pricing.

0.76, balancing high quality and competitive pricing.

(4) Comprehensive Customization Services

① Supports customization of multiple materials and processes, with flexible adjustments to size and patterns according to customer needs.

② Provides supporting cross-border logistics services.

Whether for SME promotions, high-end brand customization, or cross-border bulk procurement, LIJIE Factory is a reliable long-term partner.