How to Customize Garment Care Labels? How much?

What Are Garment Care Labels?

Garment care labels are important information tags sewn onto clothing. They convey key washing and maintenance information to consumers, printed or woven with detailed washing instructions, material composition, size details, and other content. Presented in internationally recognized symbols and text, this information helps consumers properly care for clothing and avoid damage caused by improper washing.

In today’s increasingly competitive apparel market, customizing exclusive and cost-effective garment care labels is a top priority for many enterprises.

What Makes High-Quality Garment Care Labels?

High-quality garment care labels should have the following characteristics:

① Soft and skin-friendly, avoiding discomfort when in contact with the skin

② High durability, able to withstand multiple washes without fading or tearing

③ Clear information, with legibly printed symbols and text

Material Customization for Garment Care Labels

Before customizing garment care labels, it is crucial to understand the characteristics of different materials. Here are several mainstream materials for garment care labels on the market:

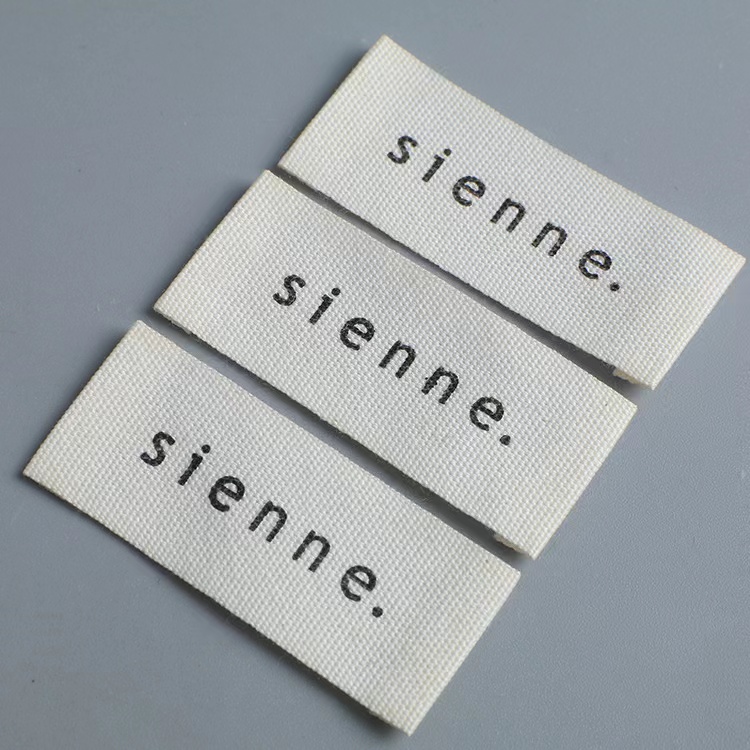

① Satin Material: Smooth and glossy surface, soft handfeel, and clear, eye-catching printing effect. Suitable for mid-to-high-end clothing such as suits, formal wear, and branded fashion apparel.

② Cotton Labels: Made of natural materials, they are skin-friendly and highly breathable. Commonly used for clothing categories with high skin sensitivity requirements, such as children’s wear and underwear.

③ Nylon Material: High durability, wrinkle-resistant and waterproof. Suitable for clothing that requires frequent washing or exposure to water, such as sportswear and swimwear.

④ TPU/Silicone Labels: High flexibility, suitable for direct skin contact. Often used for intimate apparel and high-grade casual wear.

⑤ Eco-Friendly Materials: Made of recycled polyester or organic cotton, complying with modern environmental concepts, and are increasingly favored by sustainable fashion brands.

How to Customize Garment Care Labels?

1. Submit Customization Requirements

Provide your detailed needs, including design drafts (preferably in CDR, PDF, or high-resolution JPG format), required quantity, material preferences, size specifications, etc.

2. Obtain Quotation and Sample Fee

The manufacturer will provide a detailed quotation based on your requirements and produce sample labels for your confirmation. Sample production usually takes 5 days.

3. Confirm Quotation and Make Payment

After sample confirmation, both parties confirm the final price, sign the contract, and arrange payment. Common payment methods include T/T (Bank Transfer) and others.

4. Production Process

Upon payment confirmation, the manufacturer starts mass production. The general production cycle is 7–10 working days, with the specific duration depending on order complexity and quantity.

5. Delivery

Shipment will be arranged according to the agreed logistics method. Common logistics options include express services such as DHL and FedEx (delivery in 7–9 days) or sea freight (15–30 days, suitable for large-volume and non-urgent orders).

Cost-Effective Choice: Which Material Is the Most Economical and Practical?

Among various materials, satin and nylon garment care labels achieve the best balance between cost and practicality.

① Satin labels are usually priced between 0.10 per piece (based on a minimum order quantity of 3,000 pieces), featuring a soft handfeel and good printing effect.

② Nylon taffeta labels are similarly priced at approximately 0.11 per piece, with excellent performance in durability and waterproofness.

For most regular clothing, these two materials can meet basic needs at a reasonable price. If your budget is limited, you can consider simplifying the design (e.g., reducing the number of colors) or appropriately increasing the order quantity to lower the unit price.

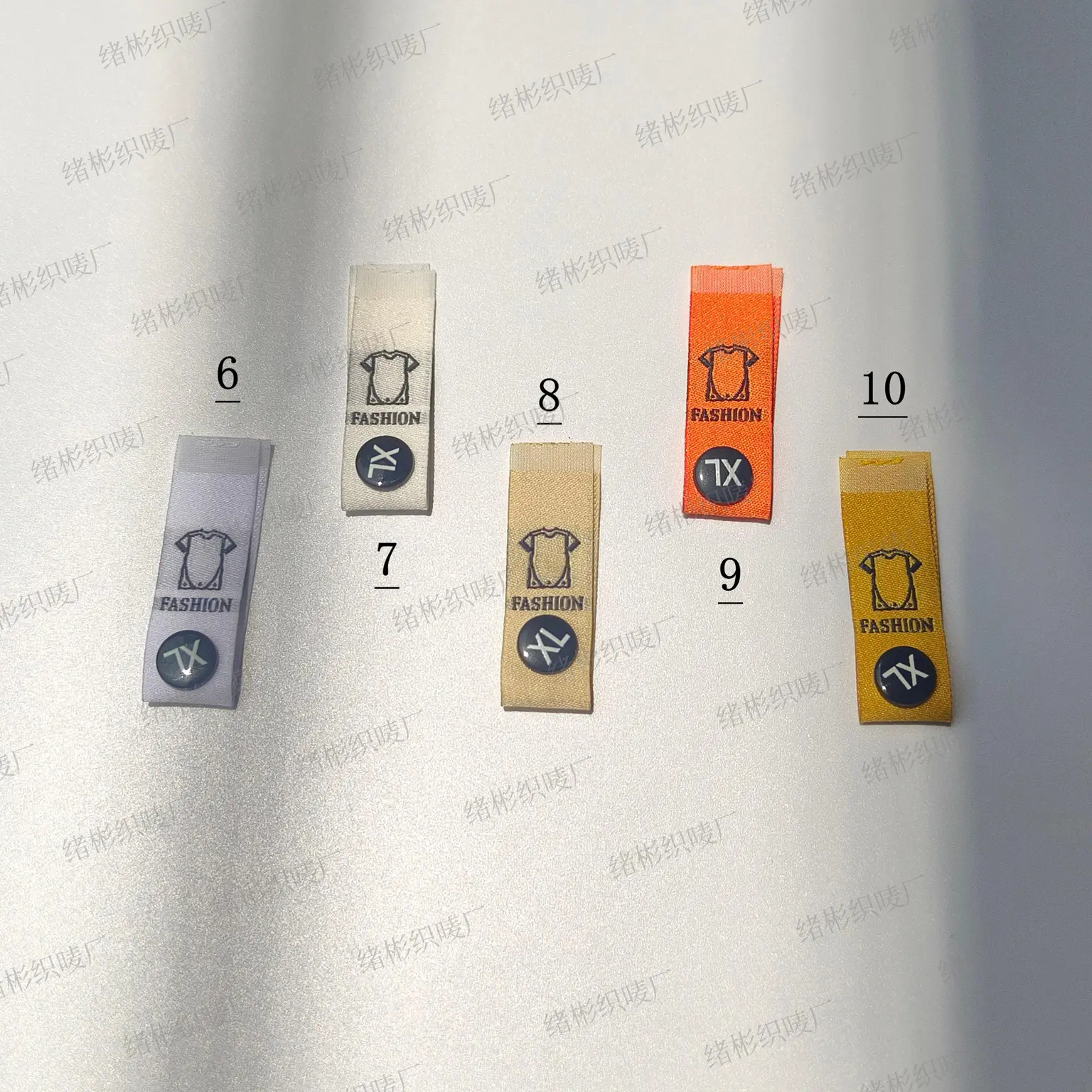

Processes and Sizes of Garment Care Labels

① Printing Technology: Screen printing, heat transfer printing, digital printing, etc.

② Cutting Methods: Ultrasonic cutting (for smooth edges), laser cutting, straight cutting, etc.

③ Folding Options: Loop fold, half fold, center fold, straight cut, etc.

④ Adhesive Types: Regular adhesive, hot stamping adhesive, self-adhesive, etc.

There are various common sizes for garment care labels, mainly determined by clothing type and label position:

① Neck labels are usually 20–40mm in width and 40–60mm in length

② Side seam labels are slightly larger, approximately 30–50mm in width and 50–80mm in length

Smaller labels are used for special clothing (e.g., baby clothes), while larger labels may be adopted for outerwear.

Garment Care Label Customization Factory

Among numerous garment care label manufacturers, China LIJIE Factory stands out with its professional production capacity and excellent product quality. As a leading enterprise in the industry, LIJIE Factory has the following advantages:

① Scale Strength: A 4,000-square-meter modern production base equipped with 30 advanced processing equipment, with a daily output of up to 1.2 million garment care labels.

② Quality Certification: Certified by multiple international standards including SGS, RoHS, and CE, ensuring reliable quality.

③ Customer Reputation: Having provided high-quality services to more than 2,000 clients, covering various clothing brands and retailers.

④ Flexible Customization: Supporting small-batch customization, with a minimum order quantity of 3,000 pieces for woven size labels, and the unit price is only 0.1, offering an extremely high cost performance.