Introduction to Clothing Hangtag Processes

Introduction to Clothing Hangtag Processes

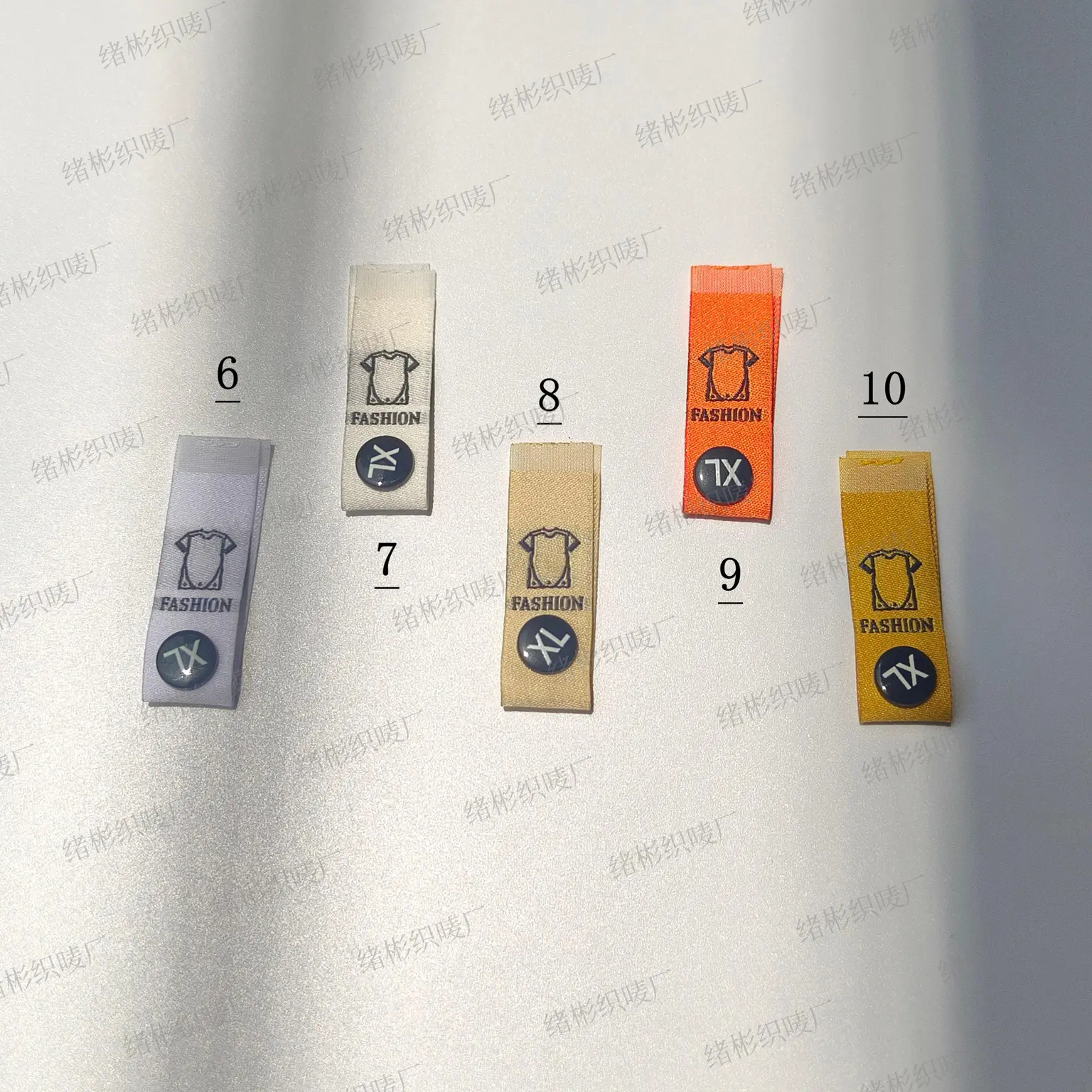

There are various processes for clothing hangtags. Different industries, and even different brands within the same industry, choose different processes for printing to showcase their brand's personality. The clothing brand printing manufacturer LIJIE in China will introduce some of the hangtag printing processes:

hnweb_

Clothing Hangtags

1. Printing: Printing the company’s logo and the necessary content on the paper.

2. Lamination: A thin layer of plastic film that increases the smoothness and flexibility of the hangtag surface.

3. Foil Stamping: Known as electrochemical aluminum foil stamping, this is a special process that does not require ink. It only needs pressure and temperature to press the paper and foil together, transferring the pattern from the foil onto the paper.

4. Embossing/Debossing: Using pressure to press patterns and designs into the paper, similar to foil stamping.

5. UV Coating: Usually used on the logo to make it appear glossy and shiny.

6. Oil Coating (Glossy Oil, Matte Oil): Prevents ink from rubbing off onto clothing.

7. Duplexing: Since printing machines can only print on paper up to 400 grams in thickness, thicker hangtags need to bond two sheets of paper together to increase the thickness.

8. Embossing Patterns: Pressing various patterns onto the paper to enhance the quality of the hangtag.

9. Eyeleting: Several hangtags are stacked together and fastened with an iron or copper ring.

10. Scoring: Creating one or more lines on the paper for easier insertion of items (such as sock cards).

11. Die-cutting: The final process for shaping the hangtag.

This is a brief introduction to the processes of clothing hangtags. We believe you now have a better understanding of which printing methods may suit your needs.

LIJIE, China, offers products that are certified for anti-counterfeiting and environmental standards, using a full set of internationally advanced production equipment to ensure the safety of your orders. We welcome your inquiries!