Types of Plastic Garment Bags

Types of Plastic Garment Bags

Plastic packaging bags are widely used in daily life, especially in the apparel industry. So, what are the different types of plastic garment bags?

There are various types of garment bags used in packaging, including:

1. Self-Adhesive Bags

2. Zipper Bags

3. Handle Bags

4. Flat-Open Bags

5. Ziplock Bags

These bags come in a range of materials such as PE, PO, PP, OPP, PPE, and CPE.

This article will provide a detailed explanation of the features of commonly used plastic bags.

Types of Garment Plastic Bags

1. Self-Adhesive Bags

Self-adhesive bags are similar to flat-open bags but include a sealing strip. They are mainly used for storing apparel, packaging gifts, or packing small items. Some self-adhesive bags come with a perforated header, making them easy to hang on display shelves for sales or visits.

There are two common printing methods for self-adhesive bags: reverse printingand surface printing.

1. Surface printingis used when ink contact with the product must be avoided.

2. Reverse printingis used when a large printed area or a smooth and glossy surface is desired since the adhesive doesn't adhere well to printed surfaces.

Typically, self-adhesive bags have a strip of glue at the opening. To use, simply peel off the small plastic strip and press to seal. Since they are mostly single-use, many e-commerce clothing brands avoid using self-adhesive bags as their primary packaging.

Example: Self-Adhesive Bags

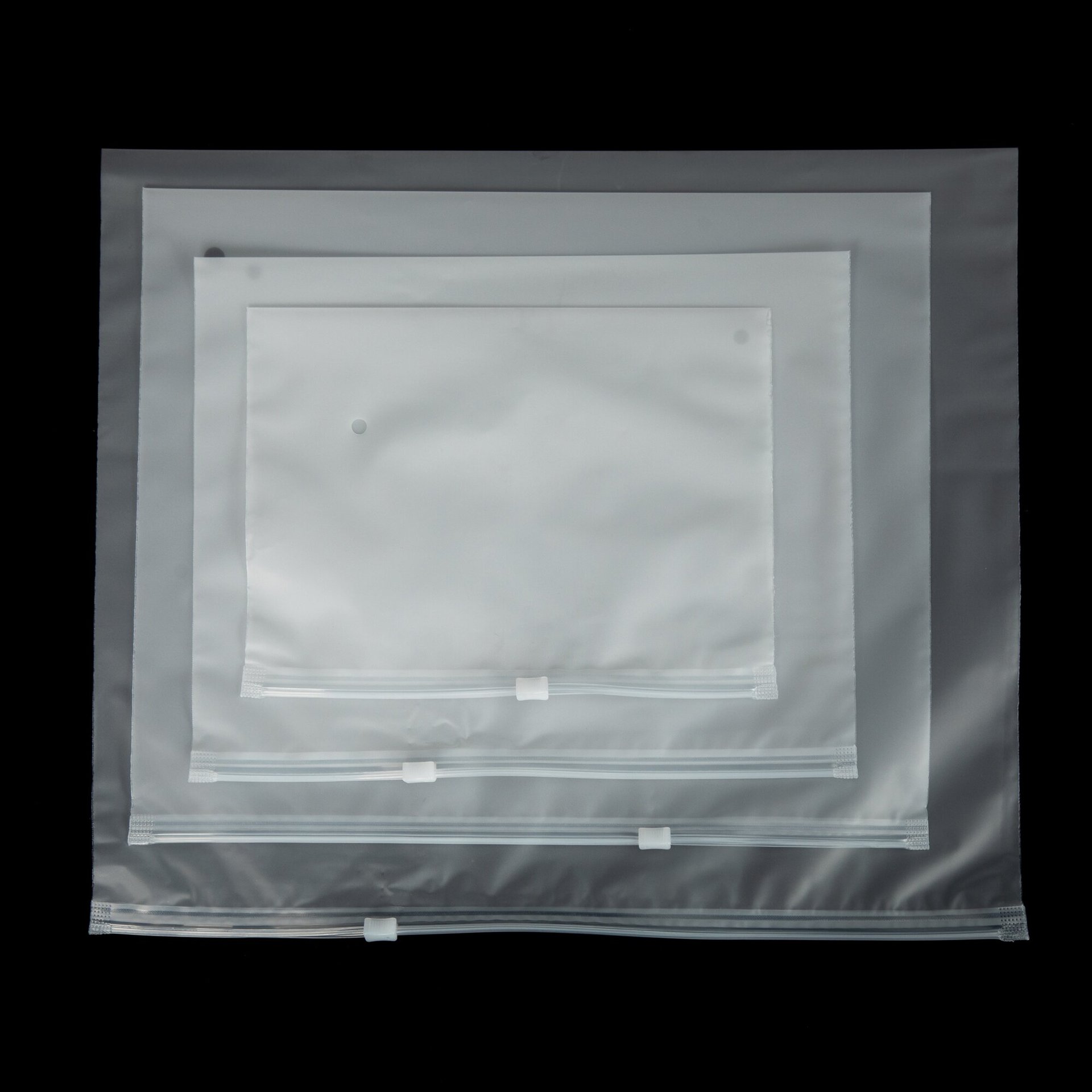

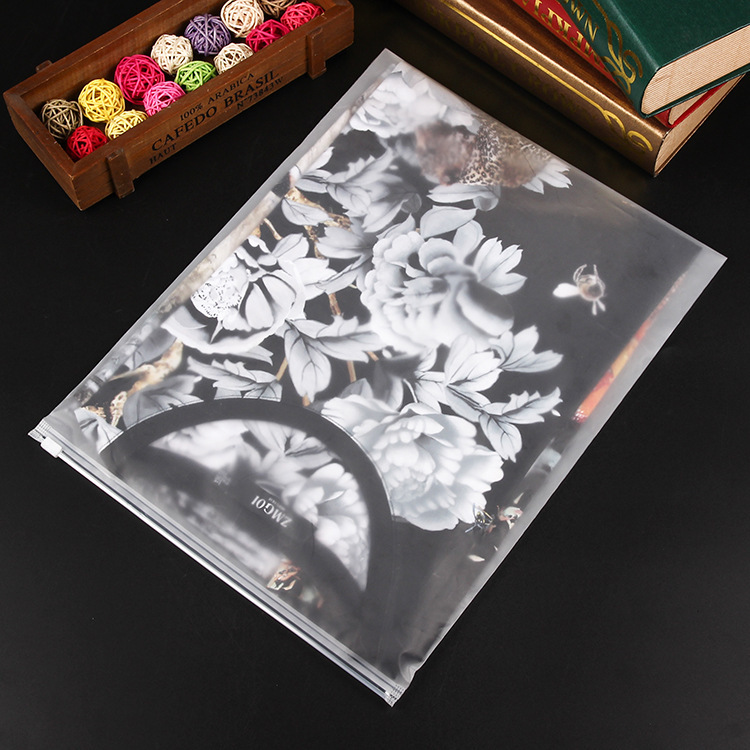

2. Zipper Bags

With the rise of e-commerce, zipper bags have gained popularity. Traditional PP self-adhesive bags often cannot be resealed properly after returns, and they attract dust during transportation. Data shows that the return rate for clothing items on platforms like Taobao can reach up to 40%, prompting brands to switch to zipper bags.

Some zipper bags now use a combination of materials—for instance, one side with frosted CPE and the other with transparent PE. This creates a high-end, elegant look when products are placed inside.

Printing:

Most zipper bags use gravure printing, which provides better visual results than flexographic printing due to its more solid printing plate. However, to reduce costs, some brands still opt for flexographic printing.

Example: Zipper Bags

3. Handle Bags

Plastic handle bags are usually categorized into four types:

1. With bottom and side gussets

2. With bottom but no side gussets

3. Without bottom and side gussets

4. Without bottom but with side gussets

Most customers prefer versions with side gussetsfor aesthetics and functionality. These designs are more structured, can stand upright, and offer additional space for branding elements like logos or QR codes.

Production Process:

Handle bags require a more complex production process than other plastic bags:

1. Side gussets are created using a folding machine.

2. Some styles need a bottom piece inserted and sealed.

3. Handles are attached using machines.

Although made of plastic, the design resembles paper bags and involves three manual steps, making them more expensive. To cut costs, some choose one-piece designs with a bottom but no sides.

Example: Handle Bags

4. Flat-Open Bags

Flat-open bags are typically made from PO or PEmaterials and are more widely applicable than other types, suitable across various industries.

They come in four structural variants:

1. With bottom and side gussets

2. With bottom but no side gussets

3. Without bottom or side gussets

4. Without bottom but with side gussets

Essentially, flat-open bags are quite similar to handle bags. The main difference is the carrying method: flat-open bags are usually punched with a hole for carrying, while handle bags have added handles. Most customers prefer the no-bottom, no-side style.

Some flat-open bags are non-punched, mainly made from CPE, PP, or OPPmaterials. These are used for packaging small items like electronics, brochures, or gifts and are generally smaller in size.

5. Ziplock Bags

Ziplock bags are most commonly used in the hardware industry, ideal for packaging screws and small parts. Common materials include PE and EVA, and sometimes multi-layer composite materials—especially for electronic components, where anti-static agents are often added.

Production Methods:

1. Blow Molding with Integrated Zipper:

The zipper and bag are formed together, which is cost-effective and widely used.

2. Attached Zipper:

The zipper is attached during bag making, usually for composite sealed bags.

For higher-end products, EVA ziplock bagsare used. These require high-frequency machines and molds to be shaped manually. While the result is visually appealing, the cost is high. Such bags are typically used for luxury underwear or lingeriepackaging.

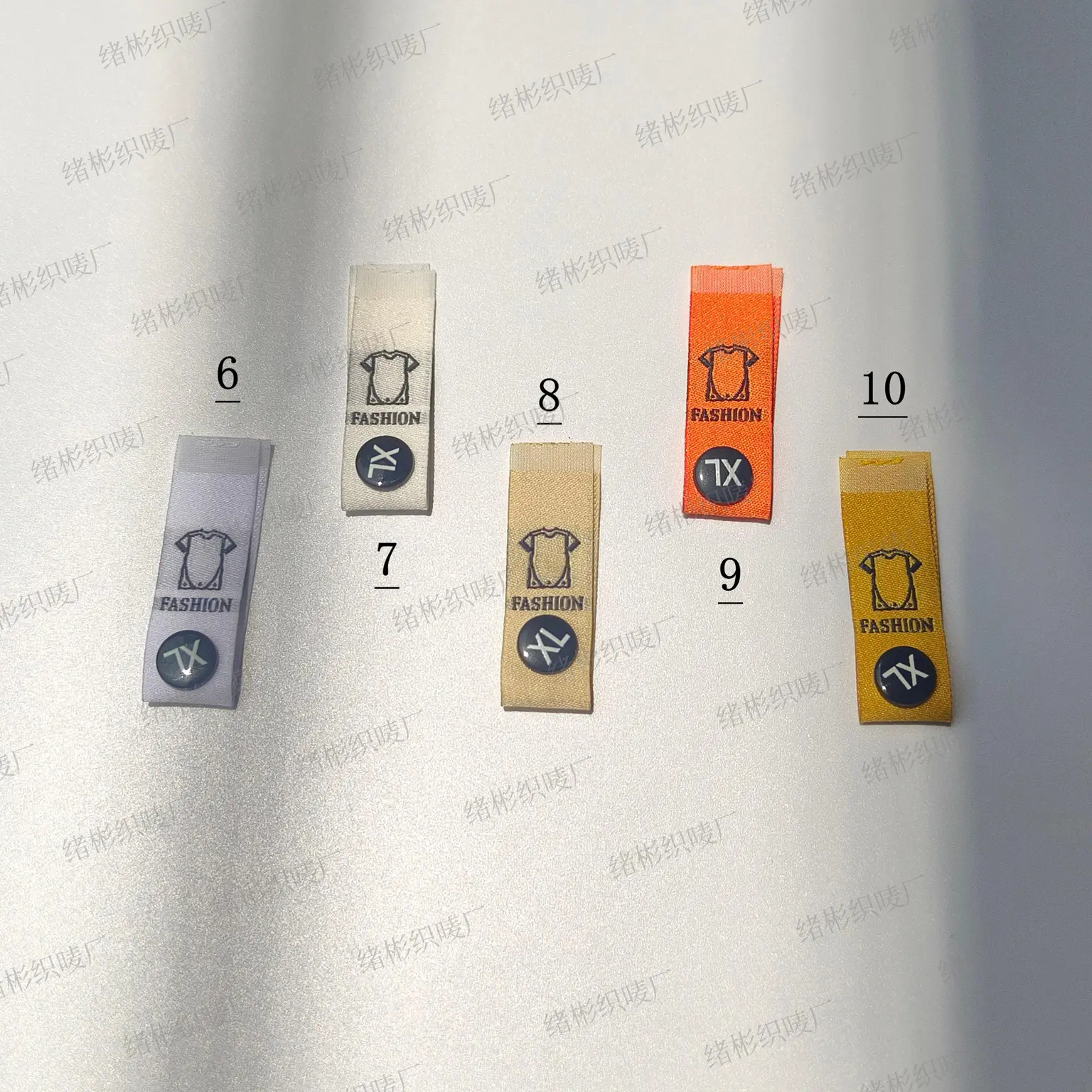

More: custom clothing price tags | luxury hang tags | waterproof clothing labels | woven satin labels