As the "identity symbol" of clothing brands, woven sew-in labels are far more than just a simple piece of fabric strip.

What Are Woven Sew-in Labels?

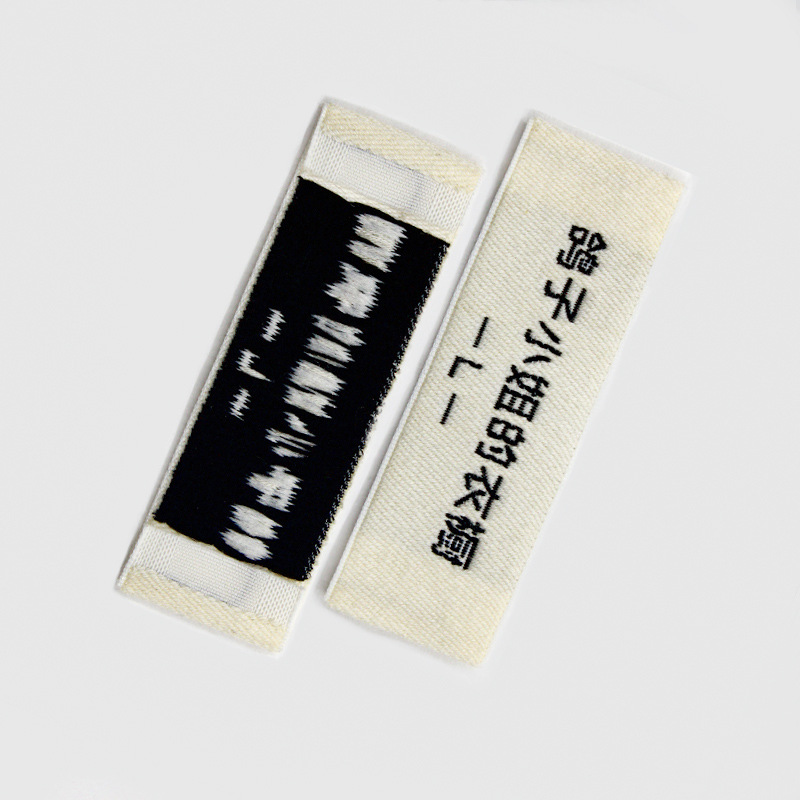

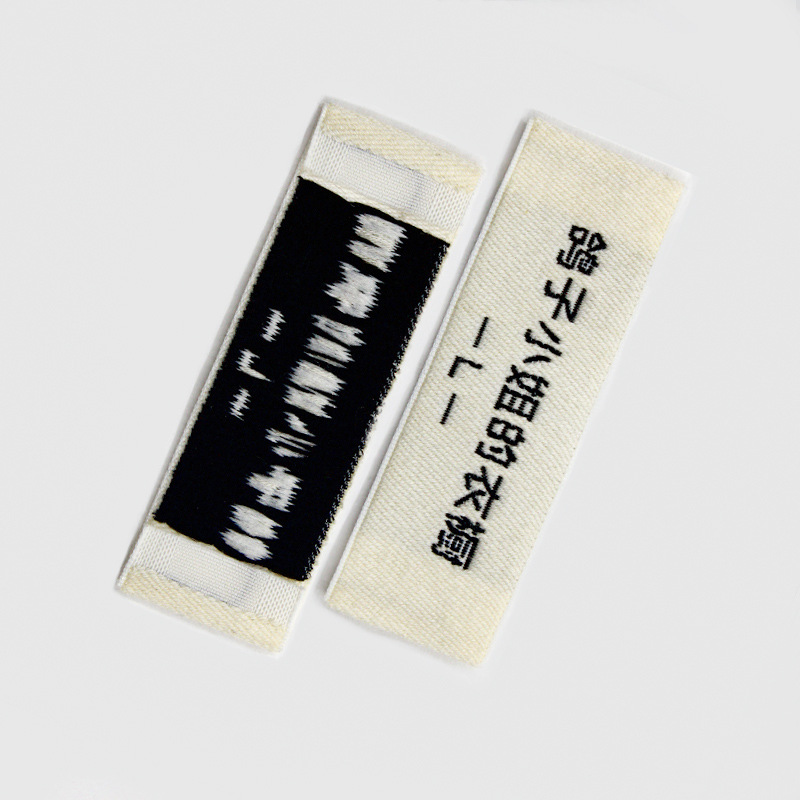

Woven sew-in labels are identification products made by interweaving warp and weft yarns on special looms and then sewn onto garments. Compared with traditional printed labels, woven sew-in labels feature excellent texture, strong durability, and a high-end appearance. They usually contain information such as brand logos, ingredient descriptions, and care symbols, serving as an indispensable component of clothing brands.

Material Types of Woven Sew-in Labels

The choice of material for woven sew-in labels directly affects their appearance, hand feel, and durability. Here are several mainstream materials:

1. Satin Material: Characterized by bright luster and smooth touch, it is commonly used in mid-to-high-end clothing brands. Satin material can effectively enhance the quality and luxury of a brand.

2. Nylon/Polyester: This type of synthetic fiber material boasts strong durability, good wrinkle resistance, bright colors, and non-fading properties. It is suitable for daily clothing that requires frequent washing.

3. Cotton Material: Cotton labels have good air permeability and a natural hand feel, making them ideal for clothing categories with high requirements for skin contact comfort, such as children's clothing and underwear.

4. Blended Material: Different materials can be blended according to specific needs. For example, cotton-polyester blended labels retain the comfort of cotton while enhancing the durability of the labels.

High-end label materials usually comply with the OEKO-TEX Standard, ensuring they are free of harmful substances and suitable for direct skin contact.

Main Types of Woven Sew-in Labels

1. Classification by Folding Method

① Center-Folded Labels: Folded along the center line to form a two-layer structure, which can display more information. They are often used for clothing that requires multilingual instructions.

② Four-Side Folded Labels: With finely processed edges, they have a more exquisite appearance and are commonly seen in high-end brand clothing.

③ Straight-Cut Labels: Featuring straight-cut edges, they are simple and modern, suitable for casual wear.

2. Classification by Function

① Main Labels (Brand Labels): Usually located at the neckline, they prominently display the brand logo and serve as the core of brand identification.

② Care Labels (Ingredient Labels): Contain important information such as fabric composition and care instructions, meeting regulatory requirements while guiding consumers to properly maintain clothing.

③ Size Labels: Clearly mark clothing sizes to facilitate consumers in choosing the right fit.

Production Processes of Woven Sew-in Labels

1. Weaving Process

1. Shuttle Loom Weaving: Produces labels with neat edges and clear patterns, and is a commonly used method for high-quality labels.

2. Shuttleless Loom Weaving: Offers high production efficiency and is suitable for mass production.

2. Cutting Process

1. Heat Cutting: Melts yarns at high temperatures, resulting in smooth edges that are not easy to fray.

2. Laser Cutting: Features high cutting precision, can achieve complex shapes, and produces more delicate edges.

3. Ultrasonic Cutting: No heating required, suitable for various materials, and maintains the integrity of labels.

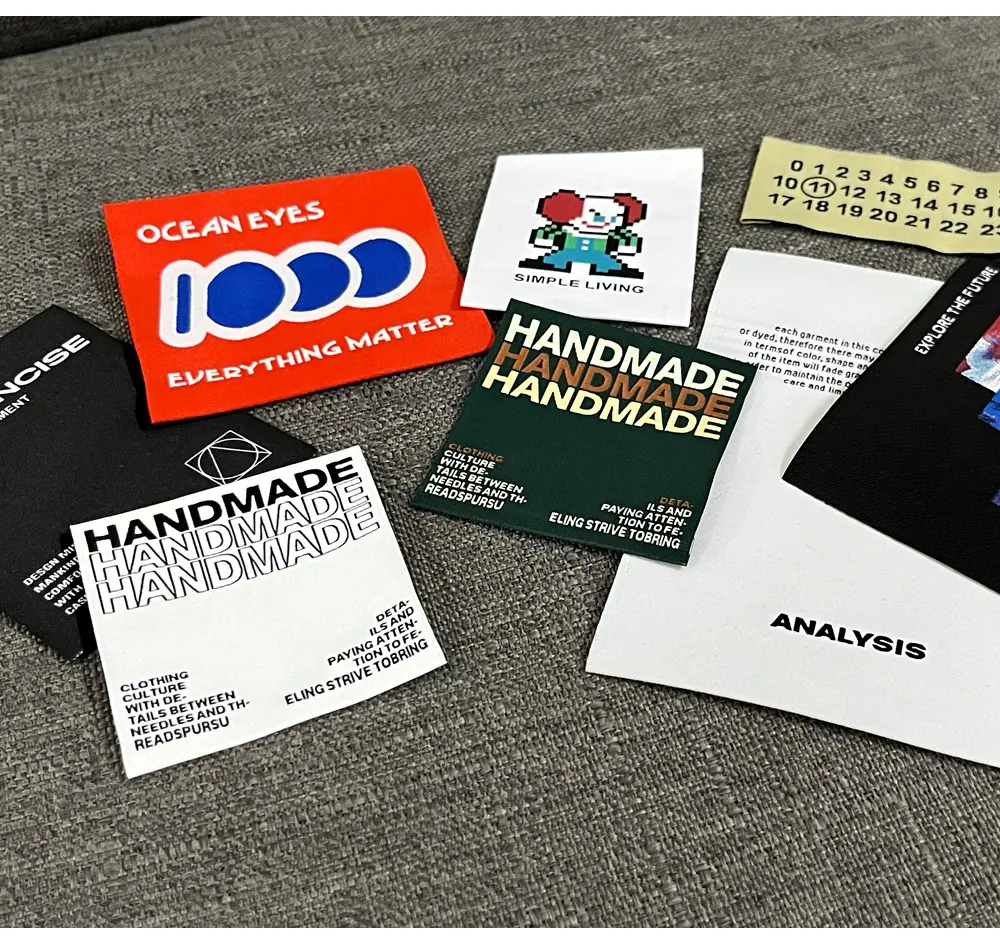

3. Printing Process

1. Heat Transfer Printing: Produces bright and durable patterns, suitable for complex graphics.

2. Digital Printing: No plate making required, suitable for small-batch customization and can meet personalized needs.

High-end label manufacturers usually hold the ISO Quality Management System Certification, ensuring that every link from material procurement to production and delivery complies with international standards.

Sewing Positions and Size Specifications

Common Sewing Positions

① Back of the Neckline: The most common sewing position for main labels, easy for consumers to view.

② Side Seam: Care labels are usually sewn here to avoid direct contact with the skin.

③ Hem: Suitable for size labels or special information labels.

④ Sleeves or Exterior Parts: Used for brand logos or decorative labels to enhance design sense.

Standard Size Range

① Width: 1–20 cm (common width for main labels: 2–5 cm)

② Length: Customized according to content requirements, usually 3–10 cm

③ Special sizes can be customized to meet the unique needs of different clothing brands.

Scope of Applicable Clothing Products

Woven sew-in labels are widely used in various clothing products:

① Upper Garments: T-shirts, shirts, sweaters, etc., with labels sewn at the neckline or side seam.

② Lower Garments: Pants, skirts, etc., with labels mostly located inside the waistband.

③ Outerwear: Jackets, coats, etc., with flexible label positions that can be arranged according to design needs.

④ Accessories: Hats, scarves, bags, etc., where labels serve both functional and decorative purposes.

⑤ Special Clothing: Underwear, swimwear, and other products with high requirements for label comfort, which mostly adopt soft materials.

Why Choose LIJIE Factory for Custom Woven Sew-in Labels?

1. Large-Scale Production Capacity: Equipped with a 4,000 m² modern factory building and 30 sets of advanced processing equipment, with a daily output of up to 1.2 million pieces, capable of meeting various large-batch order requirements.

2. Rich Experience: Has provided high-quality label products for more than 2,000 customers, covering various clothing brands and styles.

3. Quality Certifications: Passed multiple international standards including ISO Quality Management System Certification, SGS Certification, ROHS Certification, and CE Certification, ensuring reliable product quality and environmental friendliness.

4. High Cost-Effectiveness: Large-scale production brings cost advantages, with the unit price of woven sew-in labels ranging only from  0.12, offering excellent value for money.

0.12, offering excellent value for money.

5. Flexible Customization: Minimum order quantity of 3,000 pieces, providing a variety of material, process, and size options. Samples can be completed within 7 days, responding to customer needs efficiently.

LIJIE China supplies low-cost custom woven sew-in labels. The factory is located in China, and inquiries and orders are warmly welcome.