Key Considerations for Customizing Clothing Hangtags

Key Considerations for Customizing Clothing Hangtags

With 20 years of deep expertise in the clothing hangtag industry, China's LIJIE factory is committed to providing customers with high-quality hangtags. During the customization process, various details must be addressed to ensure customer satisfaction and to prevent unnecessary mistakes or complications. If you're considering custom hangtags, here are some essential aspects to keep in mind.

Have you been informed about these key factors by your hangtag printing manufacturer? Are you fully aware of them? If not, start with these fundamental details. (Customers don’t need to worry about the production process itself—what matters is the final product.) Below, we will explore essential aspects such as hangtag materials, printing techniques, dimensions, color coordination, and finishing processes.

hnweb_

hnweb_

Selection of Hangtag Materials

The majority of clothing hangtags are made from paper materials, as paper does not damage garments or packaging. Additionally, paper offers a wide range of effects (especially specialty papers) while being more cost-effective than materials like PVC, silicone, metal, plastic, or leather, which tend to be less practical and more expensive. Of course, some customers may have specific material preferences, and we always honor their choices.

Among paper materials, coated paper and white cardstock are the most common, often complemented by specialty papers for unique visual effects.

Printing Techniques for Clothing Hangtags

Generally, offset printing is the primary method for hangtag production, with screen printing used as a supplementary technique. The choice of printing method depends on the material. Most paper materials can be handled with offset printing, while certain specialty papers—such as black cardstock, silver cardstock, gold cardstock, deep blue cardstock, and kraft paper—require screen printing for optimal results.

Hangtag Dimensions and Thickness

Typically, spring and summer apparel hangtags are thinner, while autumn and winter garment hangtags are thicker. Similarly, innerwear hangtags are generally lightweight, whereas outerwear hangtags tend to be more substantial. The size and thickness of a hangtag should be both practical and aesthetically pleasing. Some designers prefer to experiment with unconventional shapes and sizes, which we accommodate on a case-by-case basis. We make recommendations based on the customer’s requirements and the actual product.

Color Coordination of Hangtags

Color selection is typically based on the product and seasonal trends. Spring and summer hangtags often feature lighter tones, while autumn and winter hangtags lean towards deeper hues. The color scheme must also align with the product’s overall aesthetic. Customers often have their own color preferences and standards, which we respect and incorporate into the final design.

Hangtag Finishing Processes

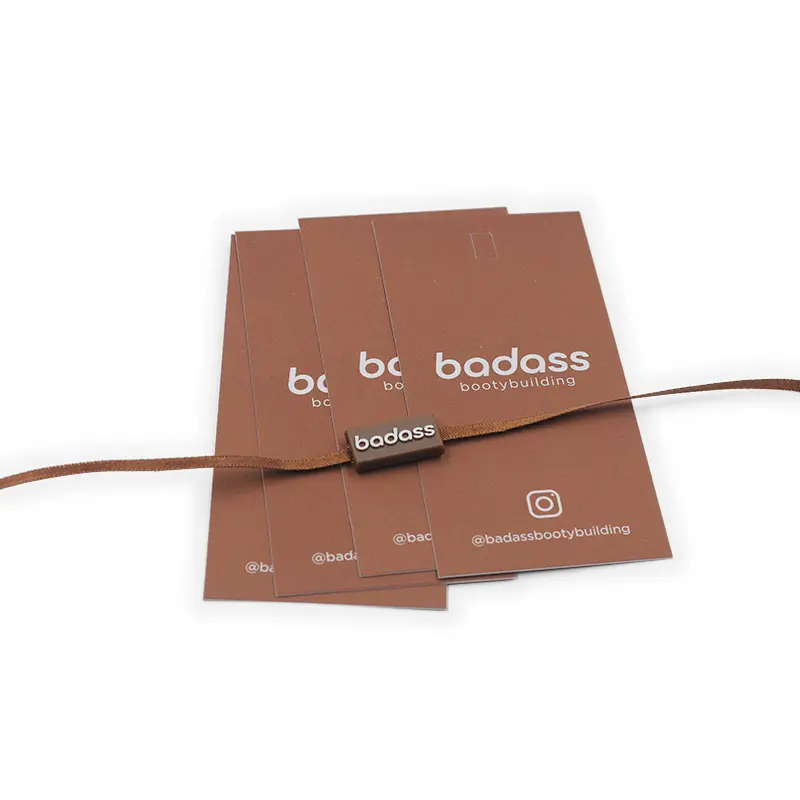

To ensure the hangtag complements the product, we offer both standard and custom shapes, along with additional finishing techniques to enhance visual appeal. These include embossing, hot stamping, debossing, UV coating, and more. Other post-processing steps include die-cutting, hole punching, inserting metal eyelets, threading hangtag strings, attaching security seals, and applying adhesive labels. Each detail is tailored to meet the customer’s specific needs.

By paying attention to these aspects, we strive to deliver high-quality, well-designed hangtags that enhance the overall presentation of your brand.