What Types of Garment Plastic Bags Are There?

What Types of Garment Plastic Bags Are There

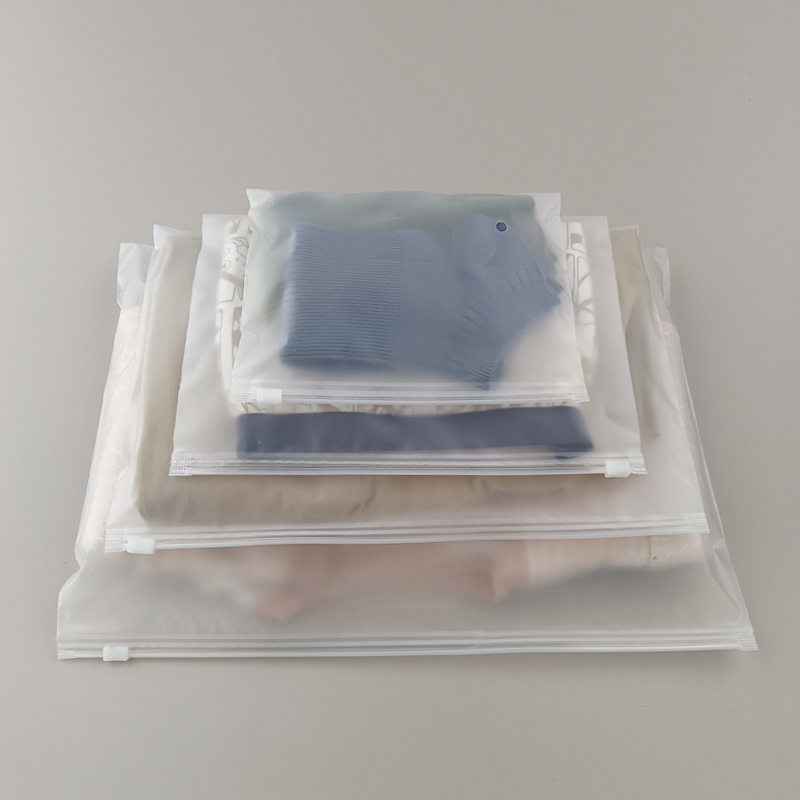

In daily life, we use various types of plastic packaging bags, especially in clothing brands. Garment plastic bags come in many types, including:

1. Self-adhesive bags

2. Zipper bags

3. Tote bags

4. Flat bags

5. Self-sealing bags

Moreover, the materials used for garment plastic bags are diverse, including PE, PO, PP, OPP, PPE, CPE, and others. This article will detail the characteristics of these commonly used plastic bags.

Types of Garment Plastic Bags

1. Self-adhesive Bags

Self-adhesive bags are similar to flat bags but feature an additional sealing strip. These bags are commonly used for storing clothing, packaging gifts, or small items. Some self-adhesive bags come with a perforated card header at the top, which allows them to be hung on a shelf for easy display and sale.

There are two printing methods for self-adhesive bags: inside printing and surface printing. Inside printing is chosen when a smooth, shiny surface is desired, while surface printing is often used to prevent ink from transferring onto the product. The self-adhesive bags have a small strip of adhesive that can be peeled off to seal the bag. Since these bags are typically one-time-use, many e-commerce clothing brands have moved away from using them.

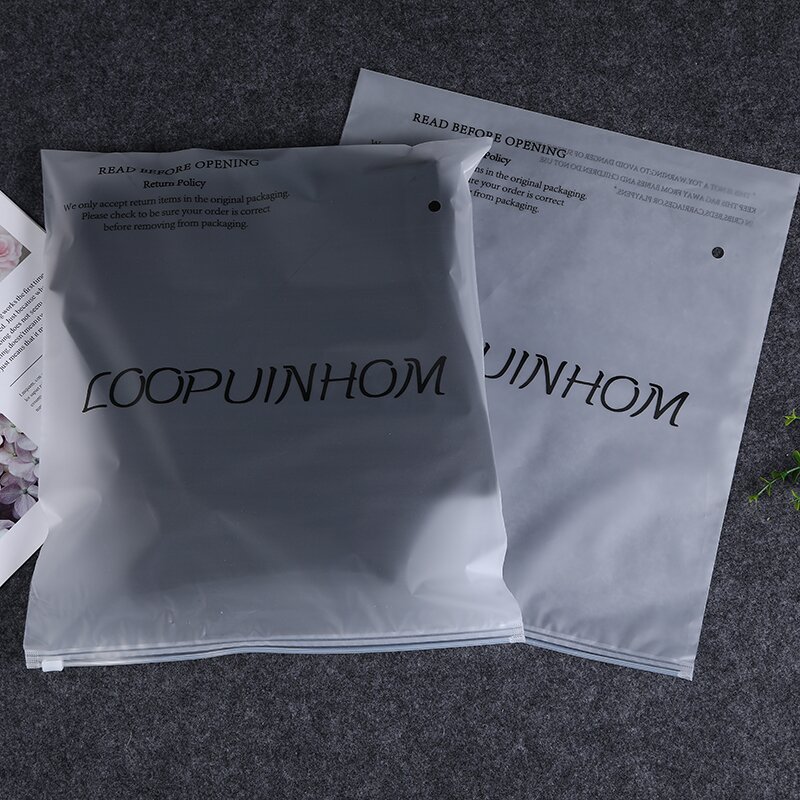

2. Zipper Bags

Zipper bags have become popular due to the rapid development of e-commerce. Traditional PP self-adhesive bags often fail to reseal properly, causing issues with returns. Zipper bags offer a more secure and reusable option, making them especially suitable for products with high return rates, such as clothing.

Some brands use zipper bags with two different materials: one side of the bag is made from CPE matte material, while the other side is made of transparent PE. This contrast enhances the appearance and gives the product a high-end feel.

Most zipper bags are printed with copperplate printing because it produces more uniform and aesthetically pleasing results compared to gravure printing. However, some brands still use gravure printing to reduce costs.

3. Tote Bags

Plastic tote bags are typically divided into four types: with bottom and side gussets, with bottom but no side gussets, with no bottom or side gussets, and with no bottom but side gussets. Most customers prefer the style with side gussets because it is more visually appealing and functional. It helps the bag stand up on its own and provides additional space for branding such as logos, designs, or QR codes.

The production process for tote bags is more complex than for other plastic bags. After printing, the side gussets are folded using a folding machine, and the bottom is either folded manually or machine-sealed, followed by attaching the handles to the top of the bag. Because of the additional steps involved, tote bags are more expensive to make compared to other styles.

4. Flat Bags

Flat bags are widely used across various industries and are made from materials such as PE and PO. They are similar to tote bags, but instead of handles, they are sealed at the top using perforations. Most flat bags are chosen in the style without bottom or side gussets, and they are primarily used to package smaller items like electronic products, books, or small gifts.

There are also non-perforated flat bags made from CPE, PP, or OPP materials, usually designed for packaging small goods with compact sizes.

5. Self-sealing Bags

Self-sealing bags are most commonly used in the hardware industry for packaging small parts like screws and components. Common materials for self-sealing bags include PE and EVA, with some bags being made of multi-layer composite materials for electronic product packaging, with anti-static additives included in the materials.

There are two main production processes for self-sealing bags: one involves blowing the zipper along with the bag during the extrusion process, which is cost-effective; the other attaches the zipper to the bag during the bag-making process, typically used for higher-end composite sealing bags. Self-sealing bags made from EVA material, which cannot be produced on a standard bag-making machine, are typically created using high-frequency machines and molds, leading to higher costs. These bags are often used for packaging high-end products like underwear.

Low-Cost Wholesale Customization Service

LIJIE in China offers low-cost wholesale garment packaging bags and supports customized production. Whether you need self-adhesive bags, zipper bags, tote bags, or self-sealing bags, we can meet your needs. We welcome all customers to place their orders.

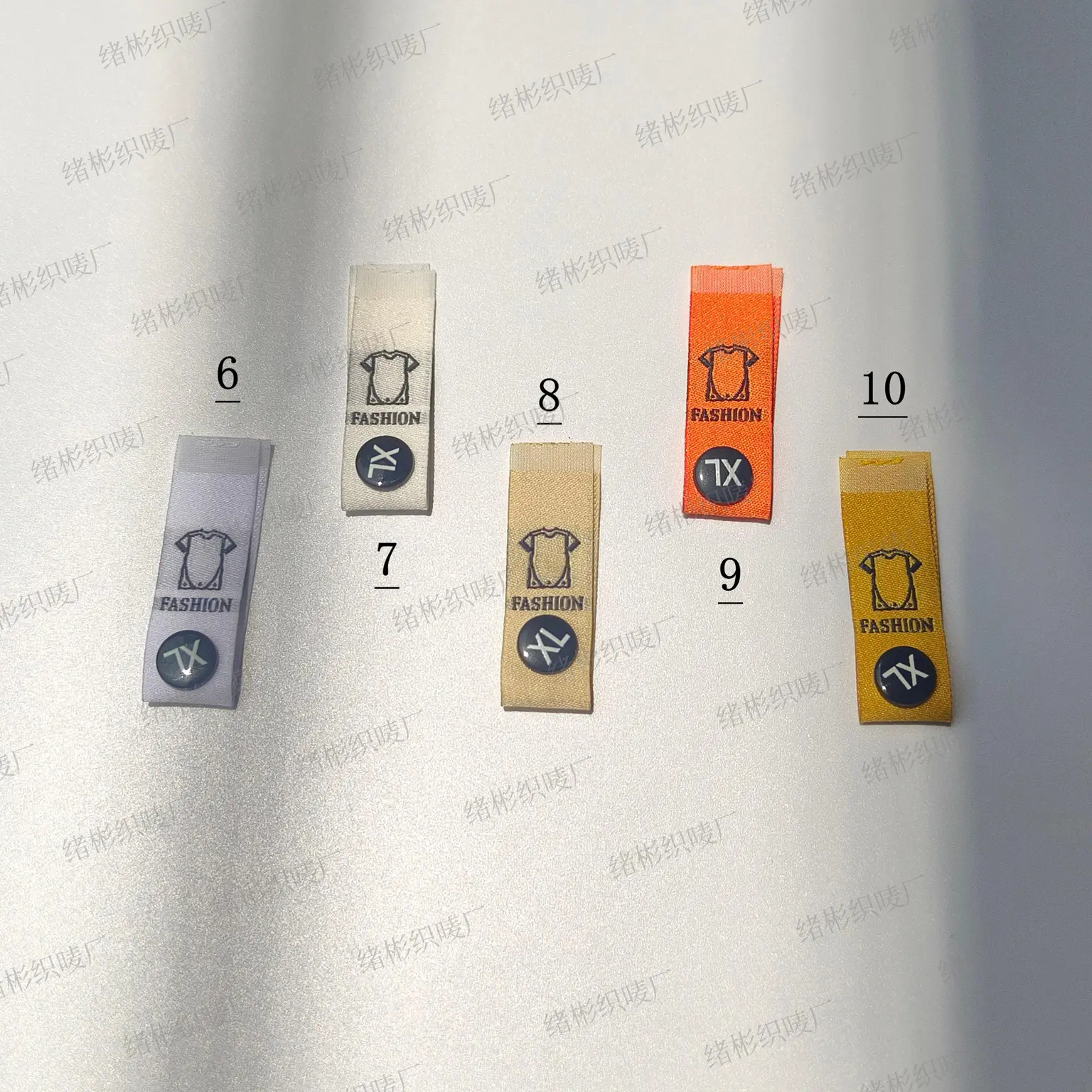

More: custom clothing price tags | luxury hang tags | waterproof clothing labels | woven satin labels