How to Customize Garment Packaging Poly Bags?

How to Customize Garment Packaging Poly Bags

How to Customize Packaging Poly Bags? What is the Customization Process for Packaging Poly Bags? What is the Production Process for Packaging Bags?

The customization process of packaging poly bags at China LIJIE generally follows these steps:

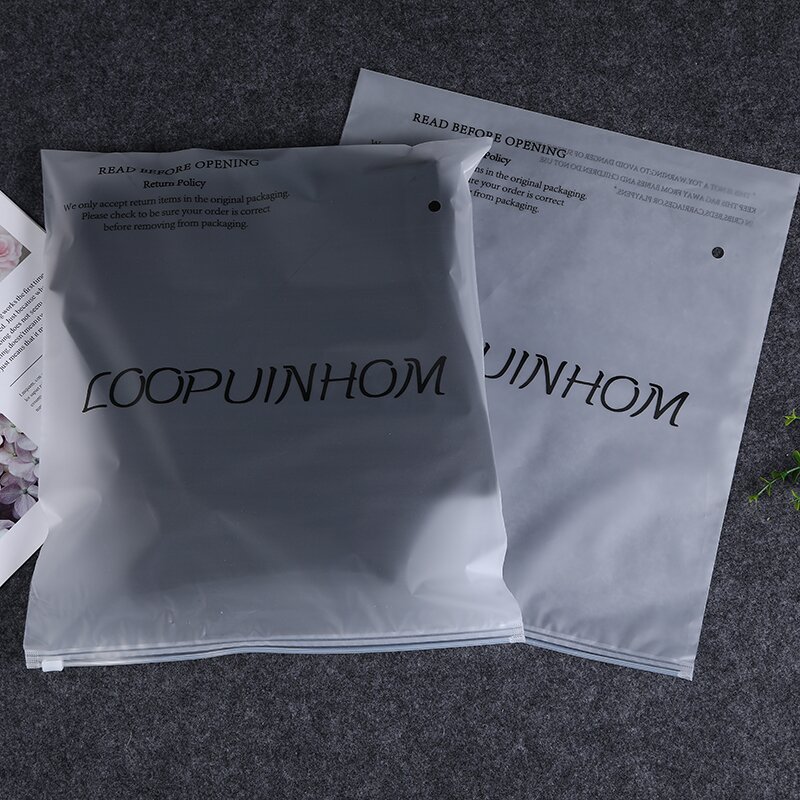

1. Provide Us with Your Packaging Bag Design.

If you don't have a design, we offer free design services. You just need to provide your logo file and some necessary information. Our professional designers will create a custom design for you one-on-one and revise it until you are satisfied.

2. We Offer You a Suitable Quotation.

Based on the size, thickness, printing, and quantity of the packaging poly bags you need, we will calculate and provide a suitable reference price for you.

3. We Can Make Free Blank Samples or Charge for Printed Samples.

If you accept our quotation, we can offer free blank sample bags for your review or produce printed samples for a fee.

4. Confirm the Sample and Place an Order by Signing a Contract.

Once the sample is confirmed and both parties agree on the price, we will sign a purchase contract and start the production process upon receiving your payment.

5. Production Completion and Delivery.

Under normal circumstances, production will be completed within 15 days. After production, we will notify you to arrange pickup by logistics or driver.

6. After-sales Service and Support.

If you encounter any issues or have questions during the use of the packaging bags, you can contact us anytime. We will provide prompt assistance.

Packaging Bag Production Process

Step 1: Film Blowing

Film blowing is a plastic processing method where plastic pellets are heated and melted, then blown into a film. Typically, polymers are extruded into tubular film under good melt flow conditions and expanded with high-pressure air to the required thickness, then cooled and set into film. Based on the order, we mix plastic pellets with color masterbatch in the film-blowing machine to produce packaging film that meets customer specifications.

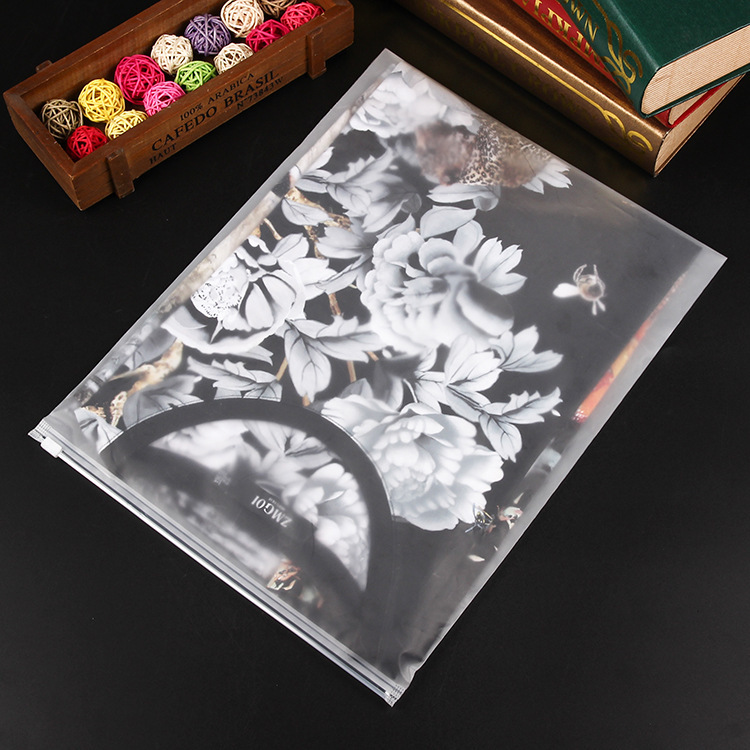

Step 2: Printing

China LIJIE is equipped with a 10-color high-speed gravure printing machine operating at 250 meters per minute, ensuring accurate and efficient printing. Our printing technicians adjust colors and align the machine to ensure clean, precise prints with no ghosting.

Step 3: Bag Making

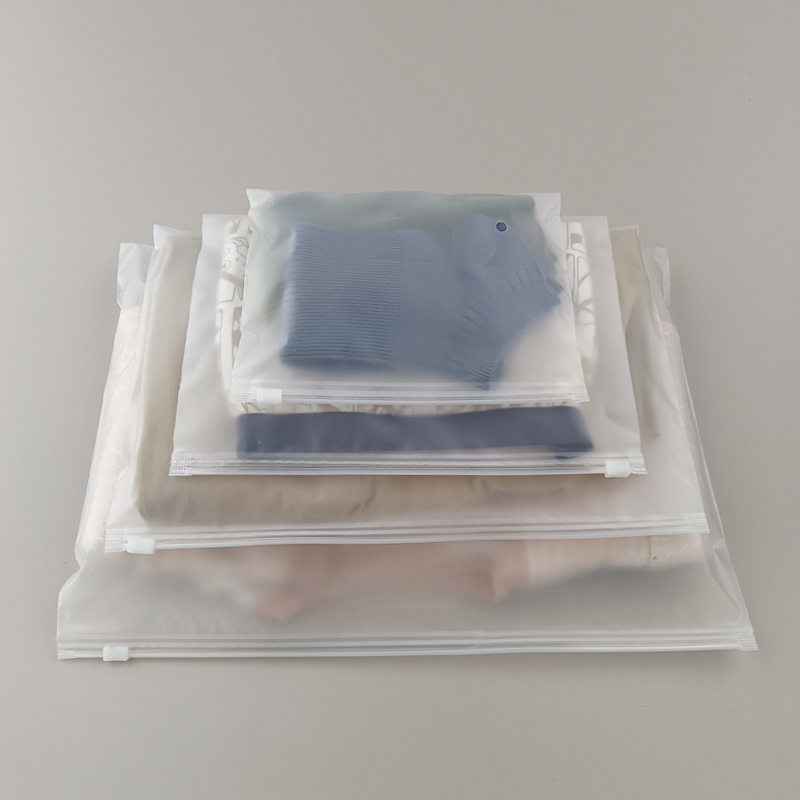

China LIJIE has dozens of bag-making machines, capable of producing various products such as flat plastic bags, zipper bags, self-adhesive bags, die-cut handle bags, plastic shopping bags, and plastic handle bags.

What Are China LIJIE’s Advantages as a Plastic Bag Manufacturer?

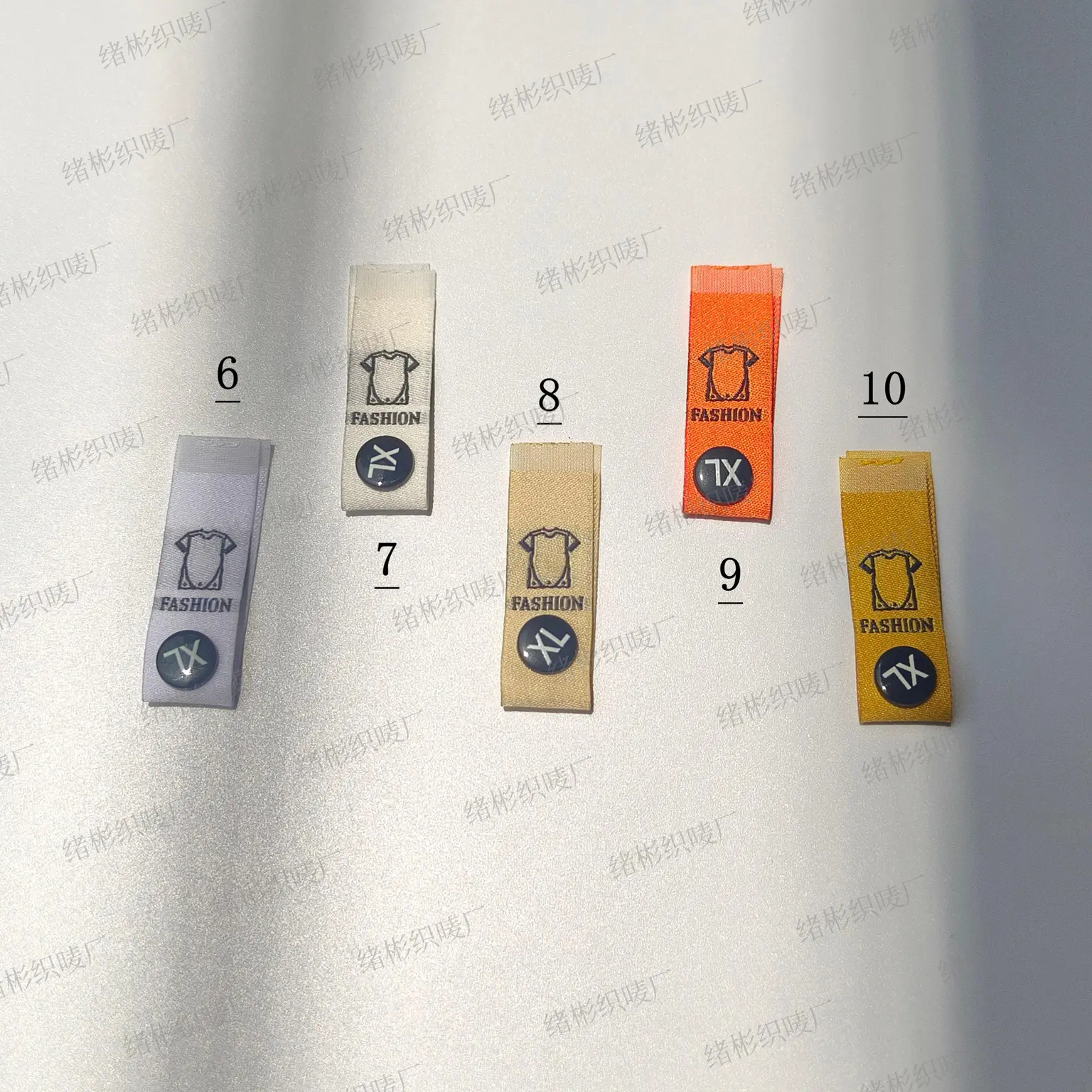

With 18 years of experience, China LIJIE is a packaging bag manufacturer located in Shenzhen, providing one-stop services for woven labels, hang tags, buttons, and packaging bags. We independently control the entire process of film blowing, printing, and bag making, ensuring stable quality and fast delivery.

China LIJIE serves a wide range of products, including plastic shopping bags, flat bags, zipper bags, self-adhesive bags, courier bags, and non-woven fabric bags, and has maintained long-term partnerships with many local Shenzhen brands.

More: custom clothing price tags | luxury hang tags | waterproof clothing labels | woven satin labels