Where to Customize Sewn Woven Labels?

Where to Customize Sewn Woven Labels

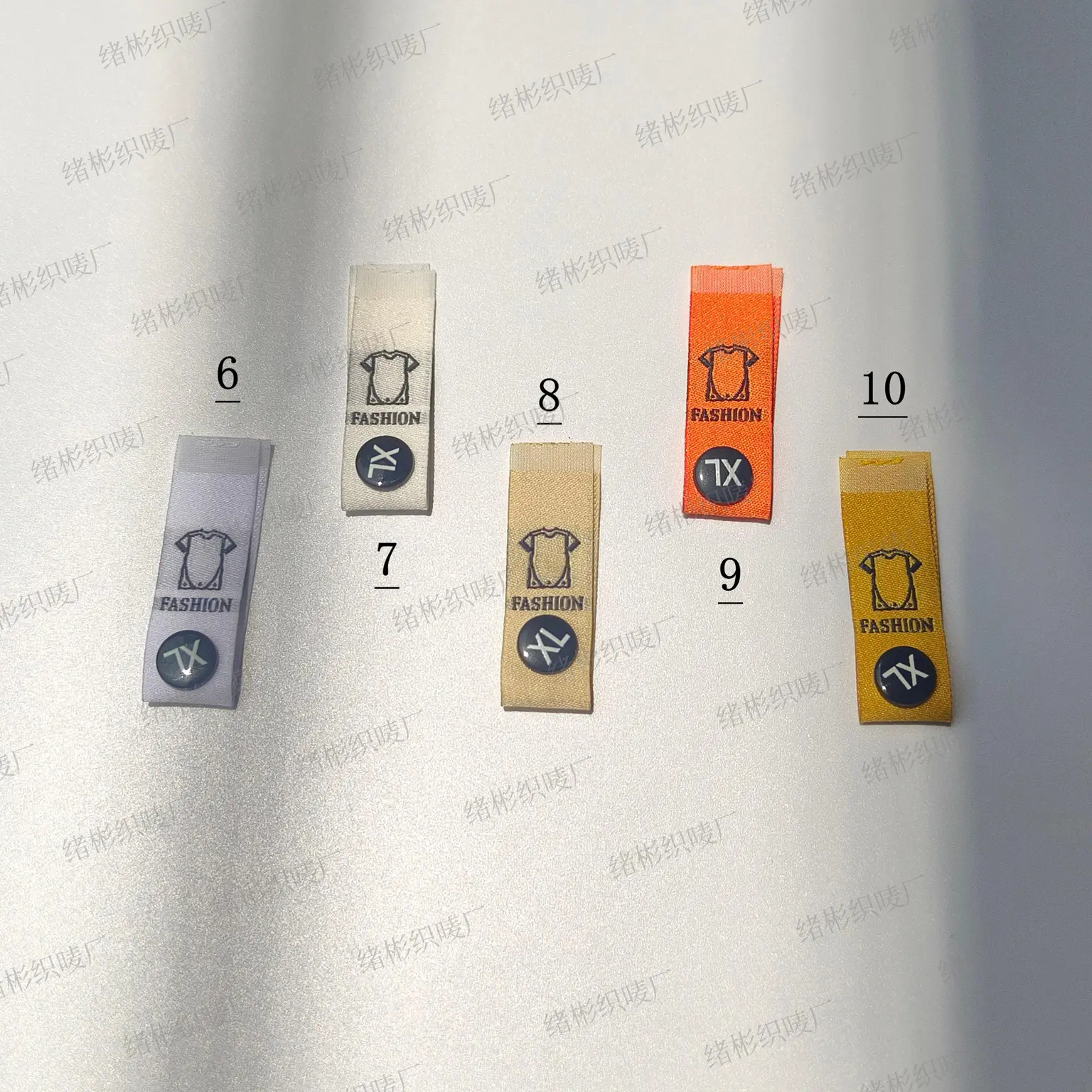

Garment details define quality— a sewn woven label is the first tactile touchpoint between a brand and its consumers. As consumer demand for “texture” and “recognition” rises, the drawbacks of traditional printed labels—such as easy peeling—and the high cost of embroidery have become apparent. Custom woven labels for sewing are emerging as a new cost-effective and efficient solution for small and medium apparel brands, offering “high aesthetic appeal + strong durability + customization.”

1. Why Are Apparel Brands Switching to Woven Labels?

A 2024 report shows:

a. 68% of consumers abandon purchases due to poor label texture;

b. 32% of brands receive after-sales complaints from label peeling or fading;

c. Demand for custom woven labels has increased by 15% over the past three years.

Compared with traditional labels, woven labels offer clear advantages:

1. Durable material:Made from cotton/polyester/blended yarns, resistant to pilling and machine washable (50 washes without fraying), outperforming printed labels (which peel easily) and heat-transfer labels (which fade easily);

2. Flexible design:Supports jacquard weaving for 3D text/patterns, with a minimum width of 1 cm (for small logos) and a maximum of 8 cm (for brand slogans);

3. Comfortable feel:Cotton labels are soft and skin-friendly (OEKO-TEX® certified), friction-free against skin, suitable for underwear and baby clothing.

2. Three Key Parameters for Custom “Sewn Woven Labels”

1. Size: Millimeter-Level Customization

Common standard width ranges from 1.5 to 3 cm (fits most garments). LIJIE supports customization from 1 to 8 cm.

For lightweight dresses, choose 1.5 cm (light and delicate); for outdoor jackets, 3 cm (easy to read washing instructions).

Length adjusts with content (each additional character extends length by 0.5-1 cm).

2. Material: Choose According to Needs

a. Pure cotton:Moisture-absorbing and breathable, ideal for underwear, babywear, and lightweight summer clothing;

b. Polyester:Abrasion-resistant and wrinkle-resistant, suitable for sportswear, work pants, and outdoor gear;

c. Cotton-polyester blend (65% cotton + 35% polyester):Balances softness and durability, a top choice for shirts and T-shirts.

3. Craftsmanship: Determines Texture Quality

a. Basic weaving:Computer jacquard weaving creates clear edges and resists deformation;

b. Post-processing:Options include gold/silver foil stamping (enhances texture), UV-resistant coating (for outdoor use), and antibacterial treatment (for maternity and baby products).

3. Why Choose Shantou LIJIE: The “Secret” to 50% Cost Savings

Traditional label manufacturers suffer from fragmented supply chains and high minimum order quantities (usually starting at 5,000 pieces), which results in high costs for small and medium brands. Shantou LIJIE breaks this deadlock through “industrial clusters + vertical integration”:

1. Cost Reduced by 50%: Factory Direct Supply, No Middlemen

Located in Shantou (one of China’s three major apparel accessory clusters), LIJIE controls the entire process of yarn procurement, weaving, and post-processing, eliminating middleman markups. The cost per piece is half that of traditional factories (e.g., a 3cm pure cotton logo label costs LIJIE $0.07–0.12 vs. $0.40–0.50 in the market).

2. Quality Uncompromised: 10-Step Inspection, Zero Complaints

With a 1,000㎡ self-owned factory equipped with automatic weaving machines and jacquard looms, LIJIE strictly controls yarn count (40s combed cotton for extra softness), colorfastness (ISO 105-C06 test), and final product precision (tolerance ≤0.1 mm). For example, LIJIE customized 100,000 baby romper labels for a children’s brand, which remained intact and unfaded after 50 washes, resulting in an 80% reorder rate.

3. Flexible Service: Small Orders Accepted

Minimum order quantity is 1,000 pieces (industry norm is 2,000), with a 7-day rapid prototyping turnaround (design to sample in as fast as 72 hours). When an emerging designer brand urgently changed their logo, LIJIE accommodated last-minute orders, delivered on time, and applied gradient jacquard weaving, helping increase product value by 15%.

4. Conclusion: A Good Label Is a Brand’s “Second Business Card”

In an era of apparel homogenization, a sewn woven label is not only a functional tag but also an extension of brand identity. Choosing LIJIE means getting “double the quality at half the price.” Through customized labels, convey your brand’s warmth — from the material (skin-friendly cotton) to craftsmanship (3D jacquard weaving).

More:content labels for clothing | custom sewn in labels | custom zipper bags with logo | wash care labels | hang tags with elastic string | hem tags for clothing