Where to Customize Woven Labels in Mexico?

Where to Customize Woven Labels in Mexico

Mexico is the second-largest apparel exporter in North America (exporting over $72 billion in 2024), with denim, cotton garments, and fast fashion items playing a significant global role. From garment factories in Tijuana to design centers in Guadalajara, Mexican apparel companies focus on “cost reduction and efficiency improvement,”with woven labels becoming a key factor in enhancing product value and cutting costs.

1. The “Label Pain Points” for Mexican Apparel Companies: High Cost, Poor Quality, and Slow Delivery

Although small, labels are the brand’s face and a compliance pass. Whether it’s care labels for T-shirts, fiber content tags on denim, or logo labels on high-end shirts, they must precisely match the fabric and usage scenario. However, local companies face three major challenges:

a. High cost:Domestic label suppliers rely mostly on manual production; raw materials are imported; hourly labor wages are about $5.5; and each label costs between $0.40–$0.60.

b. Poor quality:Some manufacturers use low-grade yarns and dyes, causing labels to pill and fade easily; in hot and humid climates, the detachment rate reaches 12%.

c. Slow delivery:From design to delivery takes 25–30 days, which cannot meet fast fashion brands’ urgent orders within 7–15 days.

These issues drive up overall costs, with returns and rework accounting for 3%–5% of revenue.

2. Woven Label Customization Solutions for Mexico

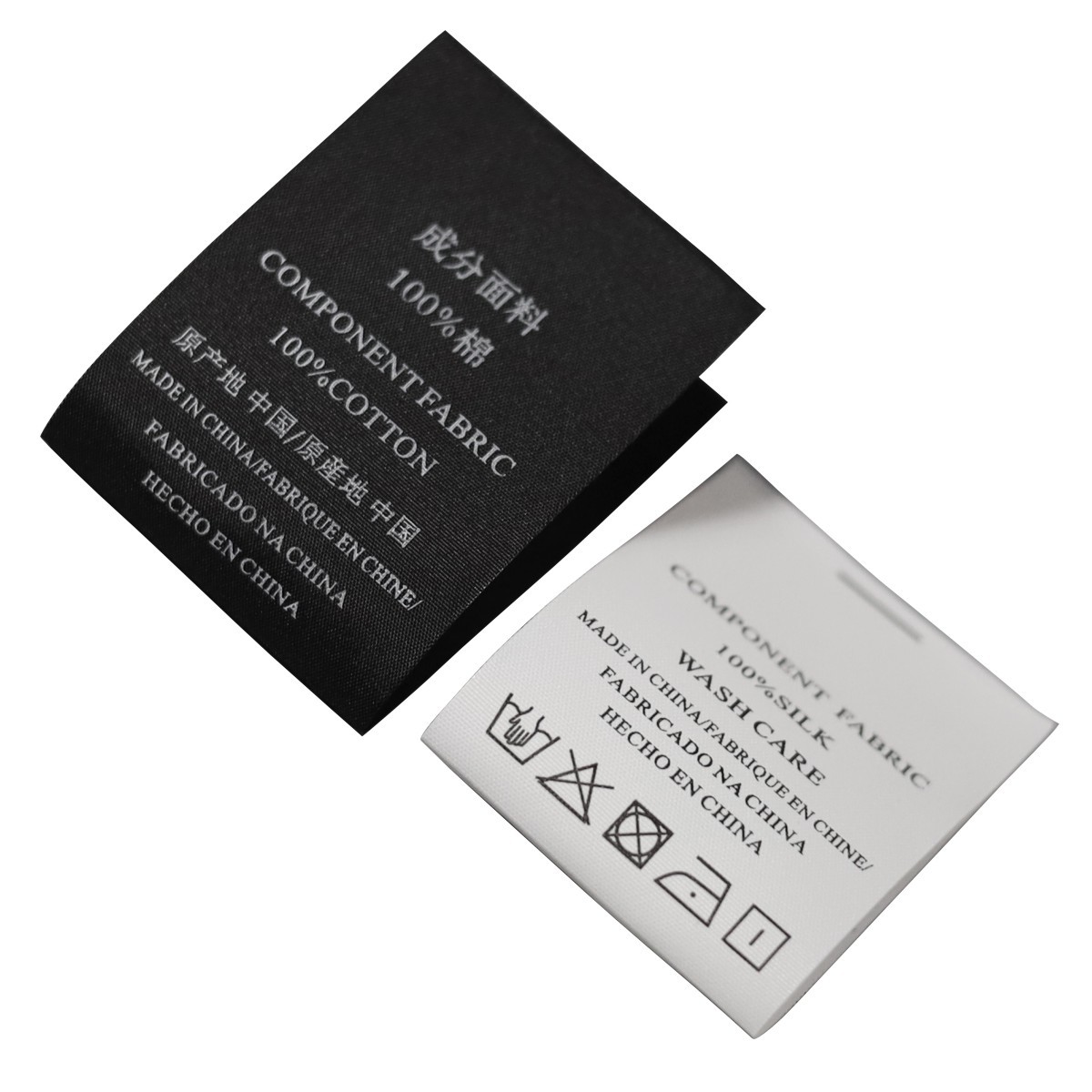

Custom woven labels are critical, offering advantages over printed and heat-transfer labels, such as durability, clarity, and eco-friendliness with no odor. They suit Mexico’s three major market scenarios:

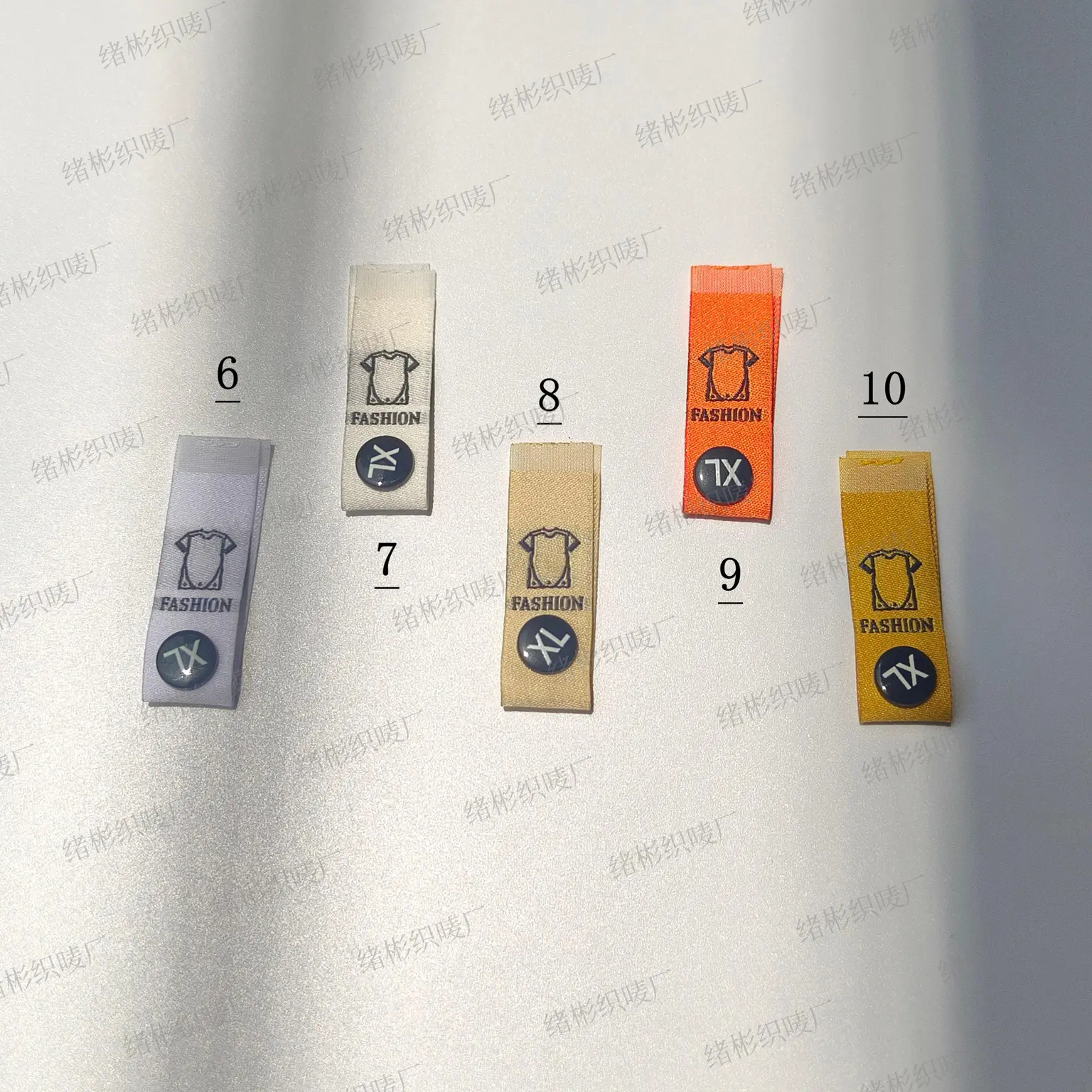

1. Size Adaptation:

a. T-shirts / Crewnecks: 10×3 cm, fitted to the neckline to avoid friction.

b. Denim Jackets / Work Pants: 12×4 cm, large size to display the logo.

c. High-end Shirts / Dresses: 8×2.5 cm, fine yarns for softness and comfort.

Chinese brand LIJIE supports a minimum order of 0.5 cm width (MOQ 1000 pieces) with a 7-day lead time, 2-3 times faster than local suppliers.

2. Material Choices:

a. Cotton-Polyester Blend (65% cotton + 35% polyester): Skin-friendly, washable, no deformation or fading.

b. 100% Polyester: Temperature resistant from -40°C to 150°C, UV and salt spray resistant, suitable for outdoor use.

3. Process Upgrades:

a. Jacquard weaving: Multi-color gradient logos with strong layering.

b. Hot stamping (Gold/Silver): Metallic coating, ideal for high-end formalwear.

c. Reflective strips: Embedded 3M reflective material to enhance nighttime safety.

3. LIJIE: Helping Mexican Companies Reduce Procurement Costs by 50%

Why choose LIJIE? Because of its “Cost-Quality-Service”advantages:

1. 50% Lower Costs

Advantages of the Shantou industrial chain:

a. Raw material procurement costs 40% less than in Mexico.

b. Automated weaving capacity of 50,000 labels per day, 20 times manual output.

c. Local warehousing and logistics respond 50% faster.

Cost per label is $0.20–$0.30, only 50%–60% of local prices.

2. Quality Assurance

Certified to CE / ROHS / REACH standards, meeting Mexican and global requirements.

Supports small batch mixed orders starting from 1000 pieces, solving high costs and fragmentation for small and medium enterprises.

More:content labels for clothing | custom sewn in labels | custom zipper bags with logo | wash care labels | hang tags with elastic string | hem tags for clothing