Polyester Woven Label vs. Cotton Woven Label

Polyester Woven Label vs. Cotton Woven Label

The material of woven labels mainly consists of yarn, with common types being polyester yarn and cotton yarn. Different materials lead to differences in the performance, appearance, and application of woven labels. Below is a comparison of cotton woven labels and polyester woven labels in various aspects, helping you make a more suitable choice:

1. Composition Differences

• Cotton Woven Label: Made from a blend of 60% cotton and 40% polyester, retaining some of the natural fiber texture.

• Polyester Woven Label: Made from 100% polyester yarn, more standardized for industrial use.

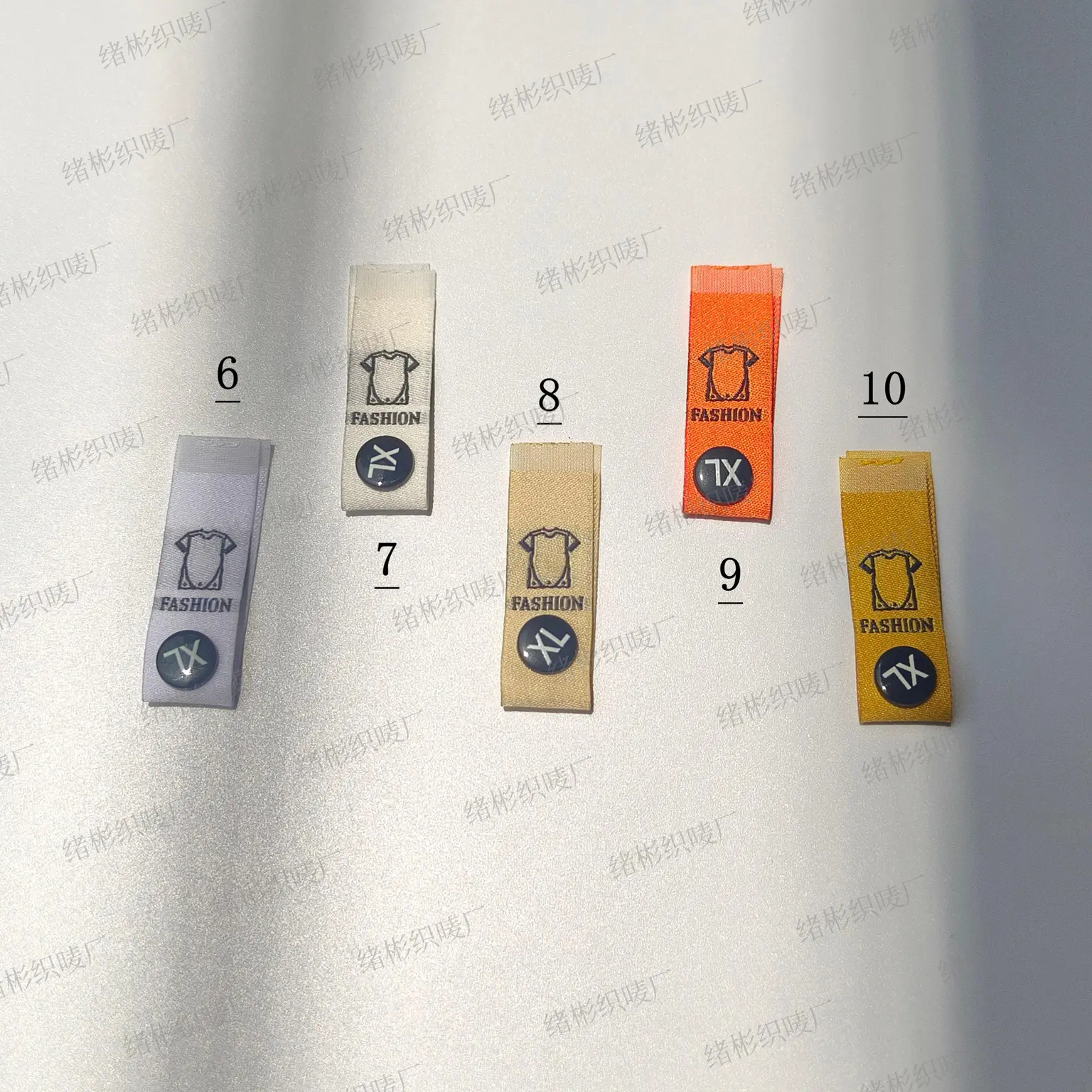

2. Background Color Options

• Cotton woven labels typically only have natural colors in stock. Custom dyeing is required for other colors.

• Polyester woven labels offer 1184 ready-made color options, greatly enhancing the flexibility of color matching.

3. Logo Color Options

Both types of labels support 1184 existing logo colors and can also be custom-dyed to meet diverse design needs.

4. Size Specifications

• Borderless Woven Labels: Both types support height customization ranging from 1 to 20 cm.

• With Border Woven Labels: Standard width ranges from 1 to 4.5 cm.

• There are no width restrictions for both types, and adjustments can be made based on design flexibility.

5. Tactile Feel

• Cotton woven labels feel softer, leaning towards a natural and comfortable style.

• Polyester woven labels also have a soft feel but are slightly less soft than cotton woven labels.

6. Stability and Fading

• Cotton woven labels have relatively poor stability, and the background color may fade slightly during use.

• Polyester woven labels have excellent stability, with colors not easily fading, making them suitable for long-term use.

7. Price Comparison

Due to the material and manufacturing processes, cotton woven labels are more expensive. Polyester woven labels offer better cost performance and are more suitable for large-scale production.

8. Application Areas

• Cotton woven labels are mainly used for cotton or canvas products, such as jackets and other natural-style clothing labels, and are not suitable for care labels.

• Polyester woven labels have a broader range of applications, commonly seen in main labels, care labels, and various brand markings.

Summary and Recommendations

• If you value texture, soft touch, and natural ingredients, cotton woven labels are a good choice.

• If you are more focused on color performance, durability, and cost-efficiency, polyester woven labels are the better option.

China LIJIE — Wholesale Woven Labels at Low Prices, Custom Orders Welcome!

Supports personalized customization and fast sampling. We welcome you to negotiate cooperation with designs and samples!

More: custom clothing price tags | luxury hang tags | waterproof clothing labels | woven satin labels