Custom Satin Clothing Labels

Custom Satin Clothing Labels

To maintain the appearance and longevity of garments, attention to detail is essential. Satin labels are favored for their softness and sheen, but their delicate nature requires proper care to ensure the garments remain intact during use. In this article, we share how to care for satin labels to keep your brand identity looking fresh, as recommended by the experts at LIJIE.

Understanding Satin Labels

Satin labels are woven from fine threads, featuring a smooth and shiny surface that enhances a garment’s brand image. However, if mishandled, the delicate fibers can be easily damaged.

Washing Satin Labels

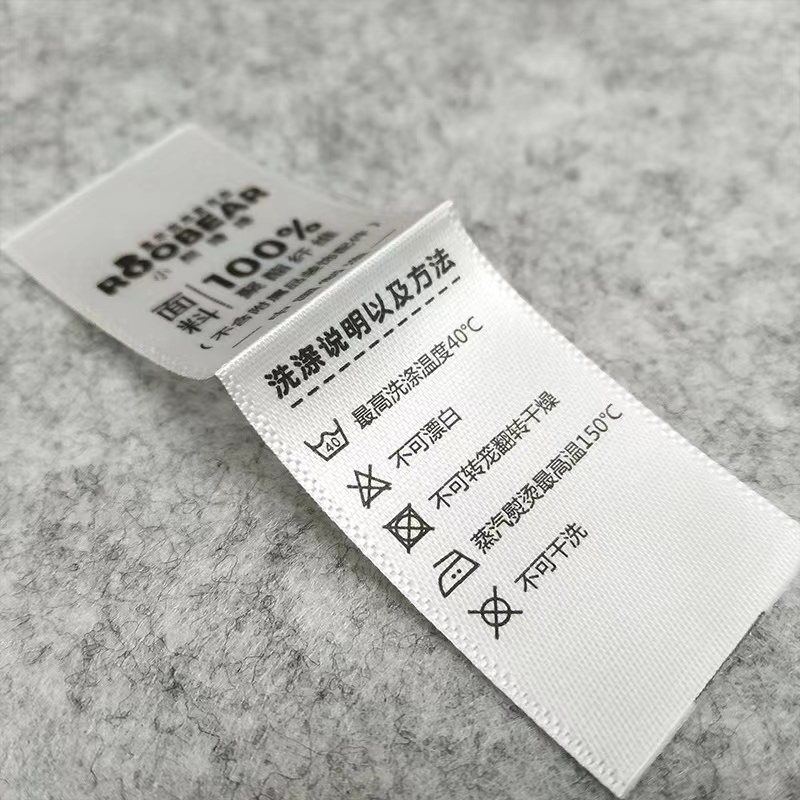

1. Check the Washing Instructions

Always refer to the care label, which usually recommends using a gentle wash cycle.

2. Use Mild Detergents

Choose mild or silk-specific detergents, and avoid harsh chemicals that can harm the label.

3. Wash with Cold Water

Hot water may cause satin to wrinkle or shrink, so it’s best to wash with cold water.

Drying Satin Labels

1. Avoid High Temperatures

High heat can damage satin fibers. Air drying is best; if needed, use a low-heat dryer setting.

2. Ironing Labels

If ironing is necessary, use a low-temperature setting and place a thin cloth over the label to shield it from direct heat.

Storing Garments with Satin Labels

1. Avoid Folding

Folding can crease the label. It’s better to hang or lay garments flat for storage.

2. Store Away from Light

Direct sunlight can cause satin labels to fade due to UV exposure. Store in a cool, shaded place.

Professional Care

For high-end garments or if unsure how to care for them, professional dry-cleaning services are recommended. Dry cleaners have the expertise to handle satin labels properly.

Satin labels add elegance to garments, but they require careful maintenance to retain their appearance. By following the correct washing, drying, and storage methods, you can ensure the labels remain durable and attractive. At LIJIE, we provide high-quality satin labels designed to withstand daily care routines. Thoughtful maintenance ensures both your garments and labels stay in excellent condition for years to come.

By following these care tips, your brand identity and garment aesthetics will be preserved over the long term, reflecting the quality and attention to detail that define your brand.