Where to Customize Sports Uniform Woven Labels?

Customize Sports Uniform Woven Labels

In 2024, the global sportswear market is valued at $287 billion (Grand View Research), with China accounting for 35% of global production. Woven labels—carrying logos, size, and care instructions—are small but critical, directly influencing consumer perception of quality.

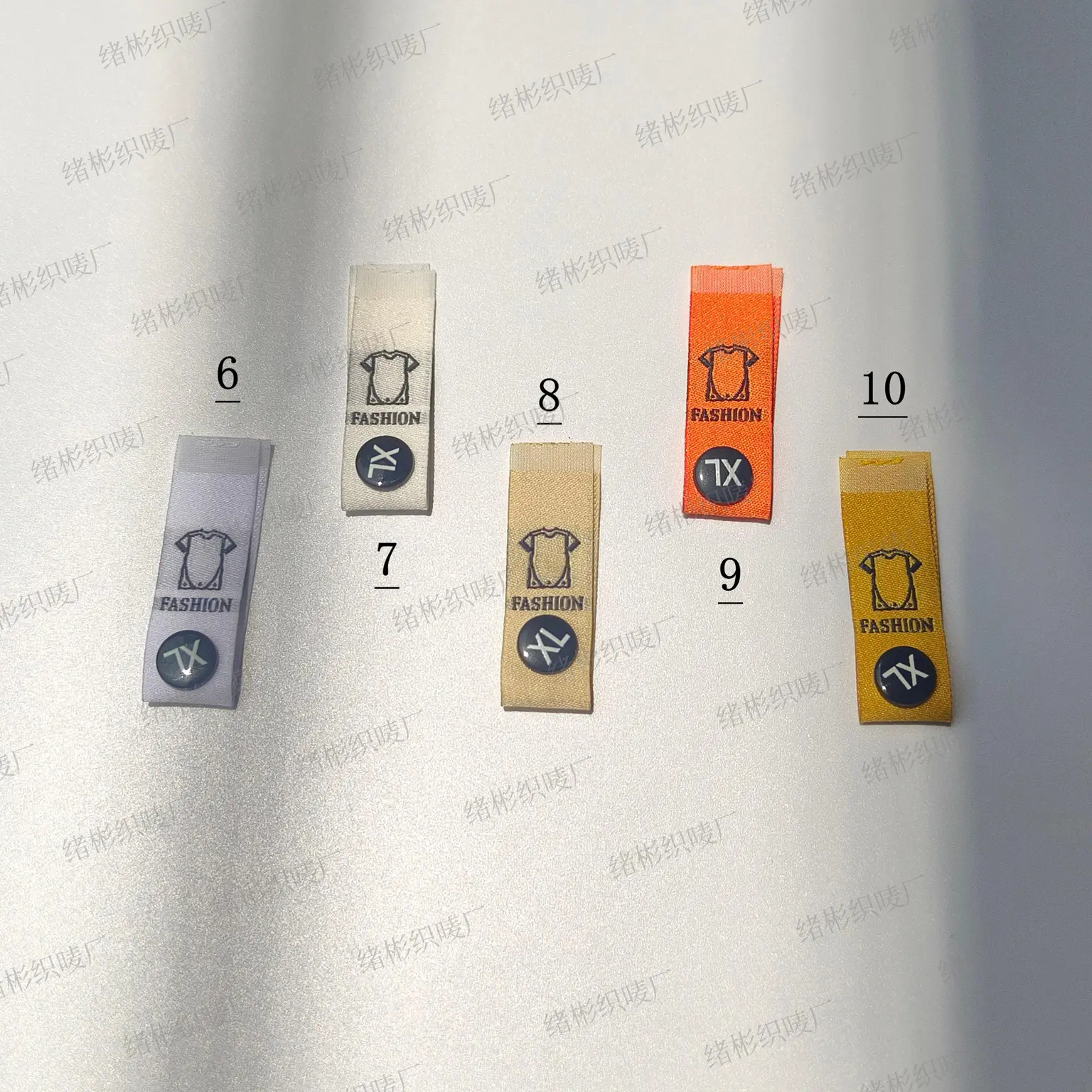

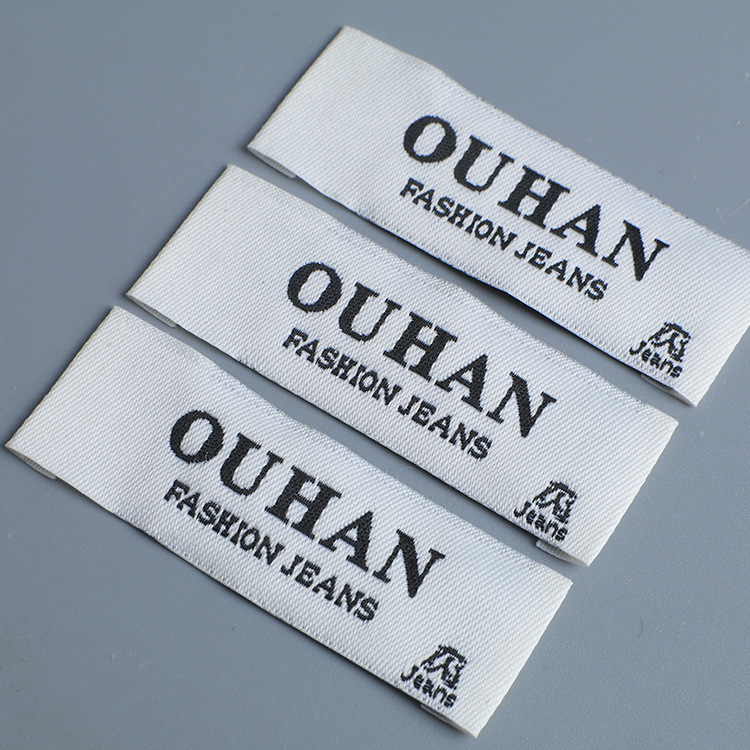

Woven Labels for Sportswear

Woven labels offer fixed text and graphics through weaving, providing better breathability, wash resistance, and smoothness compared to embroidery or printing—ideal for athletic use (e.g., running sweat, gym friction).

(1) Size: Choose Based on Application to Avoid “Friction Zones”

1. Running/Training Apparel:Tight-fit design, size 5cm × 2cm to 8cm × 3cm

2. Basketball/Outdoor Apparel:Loose-fit, size 8cm × 4cm to 12cm × 5cm (space for certification info)

3. Yoga/Fitness Pants:Discreet design, size 3cm × 1.5cm to 5cm × 2cm (usually sewn inside waistband)

Data: 68% of consumers are less likely to repurchase due to label chafing (China Sportswear Label Consumer White Paper).

(2) Material Options for Woven Labels

1. Polyester (60% share):Wrinkle-resistant and dye-friendly, common in mass-market lines; weight 180–220g/m²

2. Nylon:Highly elastic, ideal for pro wear (marathon/cycling); weight 200–240g/m² (15–20% higher cost)

3. Blends (Polyester + Cotton/Spandex):Balances comfort and performance; weight 160–200g/m² (cotton ratio should be low to avoid shrinkage)

(3) Craftsmanship: The “Hidden Standard” for Durability

1. Weaving Types:Plain (flat), Twill (textured), Jacquard (raised pattern)

2. Finishing:Anti-static (dust resistant), Soft touch (skin comfort)

3. Precision:Font edge error ≤ 0.1mm, color deviation ΔE ≤ 1.5 (Pantone standard)

Customize with LIJIE Factory – Save Up to 50% in Costs

To avoid "cheap but low-quality" or "premium but inefficient" options, LIJIE woven labels from Shantou are the top choice for sports brands—offering four core advantages:

(1) Manufacturing Hub Advantage – 30% Cost Reduction

Located in Shantou's textile cluster of 2,000+ accessory suppliers, LIJIE covers the full chain—yarn, weaving machines, post-processing—cutting out middlemen. Label prices are 30–50% lower than those in the Yangtze River Delta/Pearl River Delta.

(2) Quality Control – Triple Inspection + SGS Certification

1. Raw Materials:Only top-tier yarns from Yizheng Chemical Fiber, Hengyi, etc. (weight error ≤ ±2%)

2. Production:Uses imported weaving machines (Tsudakoma/Toyota); supports micro labels (50mm × 20mm) at 1200dpi resolution

3. Finished Goods:Tensile strength ≥ 8N, holds shape after 50 washes, ΔE ≤ 1.5; SGS report provided

(3) Flexible Customization – 7-Day Sampling, MOQ 1,000 Pieces

1. Design:Free logo-to-weave solution (avoids unweavable complex patterns)

2. Sampling:Ready within 72 hours (includes photos of material, color, size)

3. Production:Minimum order 1,000 units (vs. 5,000 industry norm)—ideal for new brands or low-volume replenishment

Three Key Factors in Choosing a Woven Label Supplier

1. Certifications:Look for ISO 9001, OEKO-TEX® (free of harmful substances)

2. Customization Capability:Supports special sizes (ultra-narrow/thin), complex designs (gradients/IP)

3. Service:Dedicated support throughout the process (design – sample – production)

LIJIE woven label unit price: $0.06 – $0.12.

More:content labels for clothing | custom sewn in labels | custom zipper bags with logo | wash care labels | hang tags with elastic string | hem tags for clothing