Custom Woven Labels for Clothing Supplier

Custom Woven Labels for Clothing Manufacturer

Woven labels are the cornerstone of branding in the fashion and textile industries. They convey brand identity, enhance the perceived quality of products, and provide essential information. The process of crafting high-quality woven labels requires precision and a harmonious blend of art, technology, and craftsmanship. Let LIJIEguide you through each step in the creation of premium woven labels.

Label Design

The manufacturing journey begins with the design phase—arguably the most critical step. Design not only defines the visual appeal but also determines the complexity of the production process. Key design elements include:

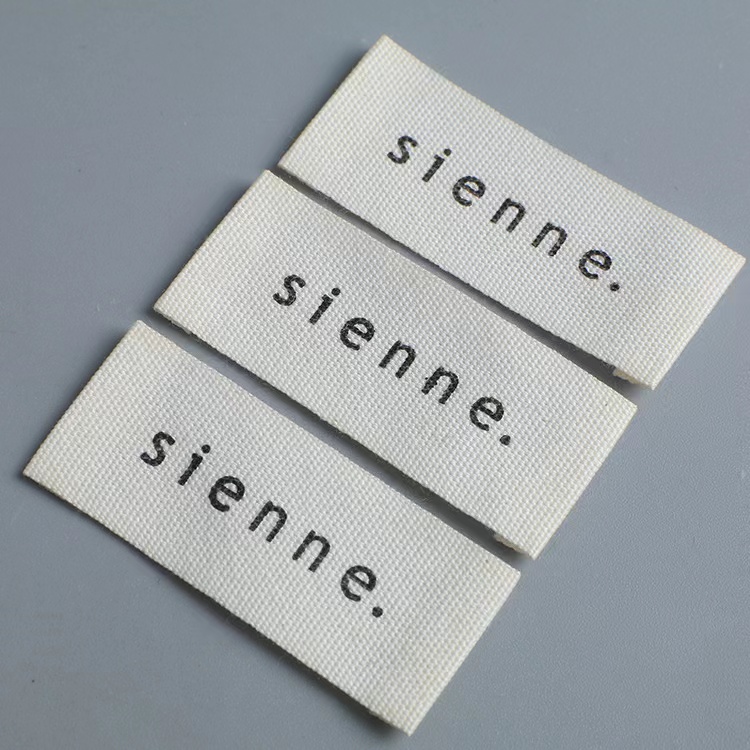

1. Logo: Must be clear and recognizable, even at small sizes.

2. Typography: Fonts should be legible and aligned with the brand’s tone.

3. Color: Pantone colors are selected to ensure accuracy and consistency.

4. Size: Dimensions are determined based on product requirements.

Designers use software such as Adobe Illustrator or CorelDRAW to create digital mockups, which are then sent to the production team for approval. This phase typically involves several rounds of revisions to ensure perfect alignment with the brand vision.

Choosing the Right Materials

Material selection plays a vital role in the label’s overall look and feel. Commonly used materials for woven labels include:

1. Damask: Soft and durable—ideal for high-end brands.

2. Satin: Offers a smooth, glossy surface for a luxurious appearance.

3. Taffeta: Crisp and cost-effective, often used for care labels.

4. Cotton: Soft and durable with excellent quality, though more expensive.

The type of thread—polyester, cotton, or metallic—also affects the texture and durability. Material selection considers not only aesthetics but also skin feel, which is crucial for apparel applications.

Color Matching and Thread Selection

Accurate color representation is essential for brand consistency. This involves selecting threads that match Pantone-certified colors during the design stage.

1. Most woven labels use 2 to 8 colors; complex designs may use more.

2. Advanced computerized looms can precisely blend these colors to match the design specs.

3. Yarn density, type, and weaving patterns are carefully chosen to achieve a perfect balance of color depth and clarity.

Loom Preparation and Weaving Setup

Once the design and materials are finalized, the loom is prepared for production:

1. Program Loading: Design files are converted into machine-readable formats to control every aspect of weaving.

2. Threading: Colored threads are loaded onto the loom according to design specifications.

3. Test Run: A test run is conducted to fine-tune settings and tension, ensuring color, pattern, and texture accuracy before full-scale production.

Weaving the Labels

The actual weaving process involves interlacing yarns on the loom to create the labels:

1. Weaving Density: Measured in picks per inch (PPI); the higher the PPI, the finer and more premium the label.

2. Weave Type: Variants like satin, plain, or twill weaves can be used to create unique textures and finishes.

Labels are woven continuously on large rolls before being cut into individual pieces.

Cutting and Folding

After weaving, the rolls are cut into single labels. Precision is crucial to prevent fraying and maintain integrity. Cutting techniques include:

1. Heat Cutting: Seals edges with heat to prevent fraying.

2. Ultrasonic Cutting: Offers smooth, precise edges, ideal for delicate labels.

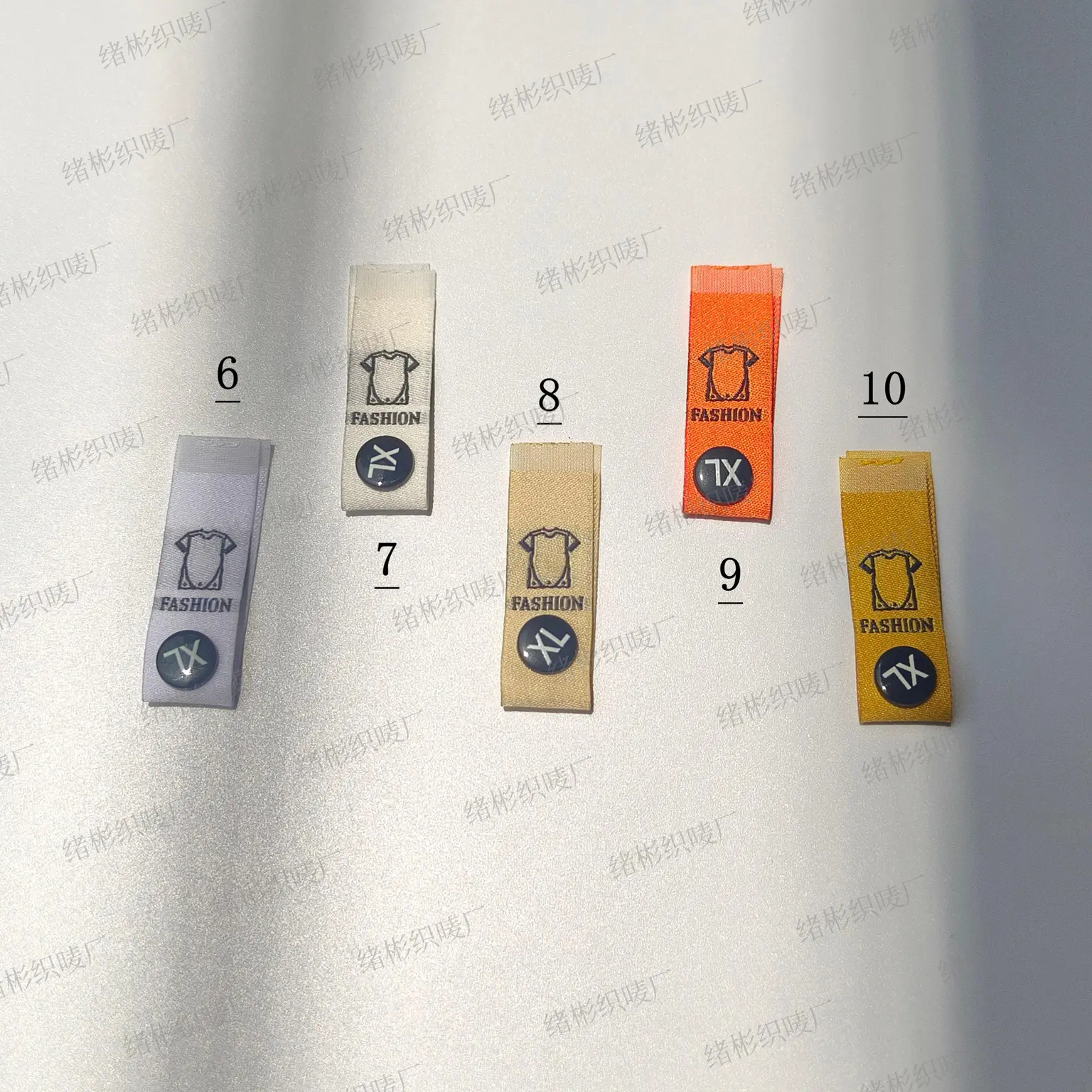

Labels can be folded in various styles depending on the intended use:

1. Straight Cut: Rectangular or square, with no folds.

2. Center Fold: Often used for neck labels.

3. End Fold: Suitable for hemlines or external seams.

4. Mitre Fold: Sewn into seams at decorative angles.

5. Loop Fold (Hanger Loop): Center-folded to form a loop, ideal for hanging.

6. Die-Cut Fold: Cut into unique shapes and folded for decorative applications.

Quality Control

Quality inspection ensures that every label meets premium brand standards:

1. Color Accuracy: Matches against approved Pantone shades.

2. Weaving Consistency: Free from loose threads, misalignment, or defects.

3. Cutting Precision: Checks for correct dimensions and fold styles.

Defective labels are removed to maintain batch quality.

Packaging and Shipping

Once approved, labels are carefully packaged to prevent damage during transport:

1. Labels are typically bundled and wrapped in protective materials.

2. They are then shipped to garment manufacturers, fashion brands, or retailers, ready to be attached to products—serving as silent ambassadors of the brand.

Producing high-quality woven labels is a detailed and intricate process. From the initial design to final inspection, every step is critical. Each phase reflects the brand’s identity and enhances the overall product experience. Whether you are an emerging fashion label or an established brand, investing in premium woven labels is a subtle yet powerful way to elevate your product quality and leave a lasting impression on your customers.

Email:royis@clothinglabelscustom.com

More:t-shirt hang tags | custom sew-on buttons | satin fabric labels | care label supplier | iron-on sewing labels | cheap hang tags | clothes zip bags | luxury hang tags | clothing neck tags | garment label manufacturer